How to Use a CNC Machine for Beginners and Enhance Your Projects?

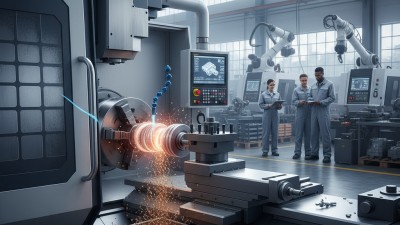

Entering the world of CNC machining can be an exhilarating yet daunting experience for beginners. As industry expert John Smith states, "Understanding the basics of a CNC machine unlocks endless creative possibilities." The CNC machine holds the key to transforming ideas into tangible projects. However, the journey is not always straightforward.

Many newcomers often grapple with the technical aspects. The initial setup can be confusing and time-consuming. Learning the interface and programming may seem overwhelming. Mistakes are common, and some projects may not turn out as envisioned. But these challenges are essential for growth. Each error provides valuable lessons that refine skills over time.

Mastering the CNC machine involves practice, patience, and a willingness to experiment. Beginners should embrace exploration and allow room for trial and error. Whether it’s crafting intricate designs or basic shapes, every project enhances understanding. Witnessing a concept come to life is undeniably rewarding, making the learning curve worthwhile.

Understanding CNC Machine Basics: Types and Functions

CNC machines, or computer numerical control machines, have changed the way we approach manufacturing and crafting. These devices automate complex tasks like cutting, milling, and engraving. Familiarizing yourself with different types is crucial for beginners. There are laser cutters, routers, and plasma cutters, each with distinct functions. For instance, laser cutters excel at precision, while routers are versatile for various materials.

Understanding the basic components of CNC machines enhances your projects. Key elements include the controller, spindle, and worktable. The controller interprets the design file and dictates movements. The spindle is the cutting tool, and the worktable holds the material in place. Mistakes often occur at this stage; calibration errors can ruin designs. It's vital to learn through trial and error. Each project can teach you something valuable, even if setbacks arise. This hands-on experience sharpens your skills and builds confidence.

Essential Safety Practices for Operating CNC Machines

Operating a CNC machine can be both rewarding and risky. Safety should always come first. Always wear safety glasses and sturdy footwear. Loose clothing can become dangerous around the machine. Secure long hair in a bun or under a cap.

Before starting, familiarize yourself with the machine. Check for any loose parts or debris. Read the machine’s manual carefully. Understand the cutting tools and their specific uses. Improper handling can lead to accidents.

When using the machine, pay attention to your surroundings. Keep the workspace clean and organized. It’s easy to overlook small hazards. Make sure emergency stops are clearly marked and accessible. Accident prevention is a continuous process. Regularly reflect on your practices to improve safety.

How to Use a CNC Machine for Beginners and Enhance Your Projects? - Essential Safety Practices for Operating CNC Machines

| Safety Practice | Description | Importance | Tips |

|---|---|---|---|

| Wear Appropriate PPE | Personal Protective Equipment protects against dust and debris. | Essential for personal safety in the workshop. | Always wear goggles, gloves, and a dust mask. |

| Read the Manual | Understanding machine functions is crucial for safe operation. | Prevents accidents and machine damage. | Take your time to understand all aspects before use. |

| Keep the Work Area Clean | A tidy workspace prevents accidents and makes operation smoother. | Reduces the risk of tripping or dropping tools. | Regularly clear debris and organize tools. |

| Perform Regular Maintenance | Regular checks ensure the machine functions properly. | Extends the machine's lifespan and reliability. | Schedule maintenance according to the manufacturer’s guidelines. |

| Know Emergency Procedures | In case of an emergency, knowing procedures can save lives. | Critical for ensuring safety in the workshop. | Familiarize yourself with emergency stops and exits. |

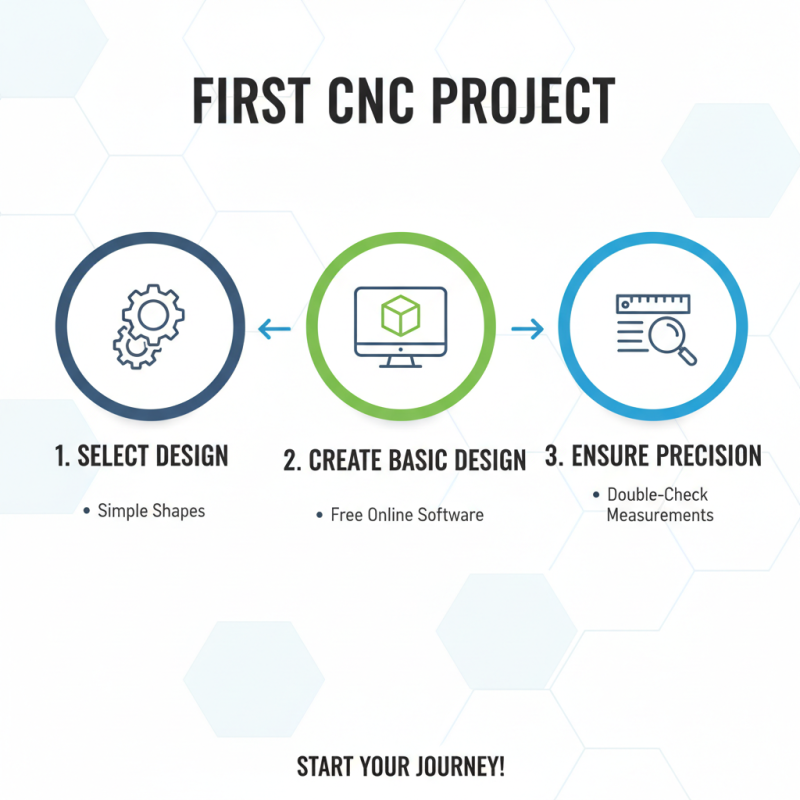

Step-by-Step Guide to Setting Up Your First CNC Project

Setting up your first CNC project can be exciting yet challenging. Begin by selecting a suitable design. Simple shapes work best for beginners. Consider using free online software to create a basic design. Ensure your measurements are precise. Small errors can lead to issues later. It's good to double-check your dimensions.

Next, you’ll need to set up your CNC machine. Familiarize yourself with its controls. Loading the material is straightforward, but be cautious. Secure the piece properly to avoid movement. Sometimes, the material can slip, ruining your work. Take your time to adjust the settings. Not all projects will turn out perfect on the first try. It's okay to make mistakes; they are part of the learning process.

After everything is set, you are ready to start machining. Watch closely and listen for any unusual sounds. They might indicate a problem. If you have doubts, pause to assess the situation. The process can be tedious, but persistence pays off. Enjoy the journey, and remember, every project is a chance to improve your skills.

Material Selection: Choosing the Right Materials for CNC Machining

When selecting materials for CNC machining, the choice can greatly affect the outcome of your projects. Metals like aluminum and brass are popular due to their machinability and durability. According to the National Institute of Standards and Technology, aluminum alloys account for 18% of the material market in CNC machining. This is because they provide excellent strength-to-weight ratios and finish quality.

Plastics like ABS and nylon are also worth considering. These materials are often easier to work with and can produce intricate designs. A report from SME indicates that 30% of CNC machined components are made from plastics. The flexibility of plastics allows for creative and unique solutions but requires careful handling. Certain plastics may warp or melt at high temperatures, which can lead to imperfect results.

Tip: Test materials before your final project. Small samples can reveal how a material behaves during machining. Additionally, always check compatibility with your CNC machine. Experimenting with different setups can save time and resources. Keep in mind that not every material will yield perfect results on the first go. This iterative process can lead to greater understanding and ultimately better projects. Assess what works and learn from the challenges faced.

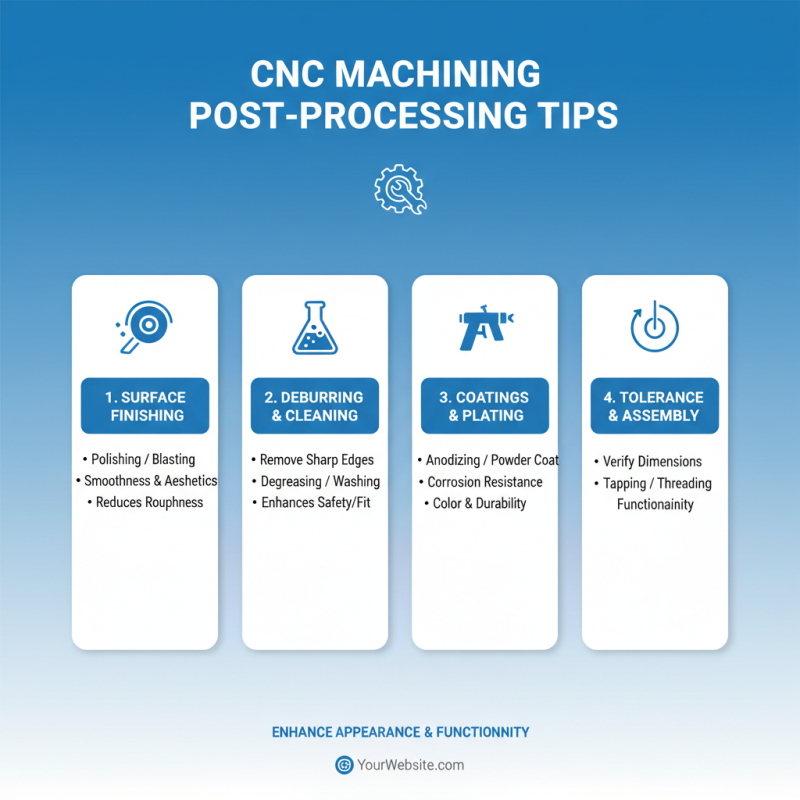

Tips for Post-Processing: Enhancing Your CNC Machined Projects

Post-processing is essential for CNC machined projects. It can significantly enhance the final appearance and functionality. Here are some tips to consider.

Start with sanding. This step removes rough edges and smooths out surfaces. Use a variety of grits to achieve a polished look. Pay attention to corners and hard-to-reach areas. Don't rush this process; careful sanding makes a difference.

Next, consider painting or applying finishes. A fresh coat of paint can bring your project to life. Choose colors that complement your design. If you are using a wood project, consider stains or clear coats. These can add depth and character. Just remember to test on scrap material first.

Lastly, assemble your project thoughtfully. Ensure all parts fit well. Adjust any misalignments. Small gaps can be obvious in the final product. Reflect on your work and be open to improvement. Each project is a chance to learn and grow in your CNC journey.

Related Posts

-

Why Choose a CNC Mill for Your Machining Needs?

-

What is a CNC Mill and How Does It Work?

-

Top 10 CNC Lathe Machines for Precision Engineering in 2023

-

Top Benefits of Fast CNC Machining for Your Manufacturing Needs

-

How to Achieve Precision with Fast CNC Machining Techniques?

-

Why is CNC Lathe Essential for Modern Manufacturing?