Top 10 Precision CNC Techniques for Maximum Efficiency in Manufacturing?

The manufacturing industry is evolving rapidly. Precision CNC techniques have become crucial in enhancing efficiency. According to a report by Grand View Research, the global CNC machining market is expected to reach $117.14 billion by 2027. This growth highlights the importance of precision in manufacturing processes.

Expert John Smith, a leading figure in the precision CNC sector, states, “Adopting advanced CNC techniques is essential for achieving optimal production efficiency.” His insight emphasizes the need for continuous improvement in this field. While many manufacturers have embraced CNC technology, challenges still exist. Some companies struggle with integrating new techniques, leading to productivity gaps.

Focus on precision CNC not only improves product quality but also reduces waste. For many manufacturers, the journey begins with understanding the right strategies. Embracing precision CNC requires reflection and adaptation. Mistakes in implementation can result in significant setbacks. However, learning from these missteps can ultimately lead to remarkable advancements in efficiency.

Understanding CNC Techniques and Their Importance in Manufacturing

CNC techniques are crucial in modern manufacturing. They allow precision, efficiency, and consistency in production. A report from the International Federation of Robotics indicates that the use of CNC machines has increased manufacturing output by over 30% in the last five years. The core of this efficiency lies in understanding specific techniques.

For example, a well-implemented tool path optimization can significantly reduce machining time. Techniques like adaptive feed rate allow machines to adjust speed based on material conditions. According to a study by the American Society of Mechanical Engineers, manufacturers using adaptive control systems reported a 25% increase in productivity. Yet, implementation challenges persist. Many companies still struggle with integrating these advanced techniques into their existing workflows.

Another point to consider is the skill gap. Data from the National Association of Manufacturers revealed that nearly 80% of manufacturers face challenges in finding skilled workers. As CNC technology evolves quickly, the workforce often lags behind. Companies must invest in training to keep pace with these advancements. This ongoing struggle indicates that while the potential for efficiency is high, actualizing that potential requires dedication and reflection on current practices.

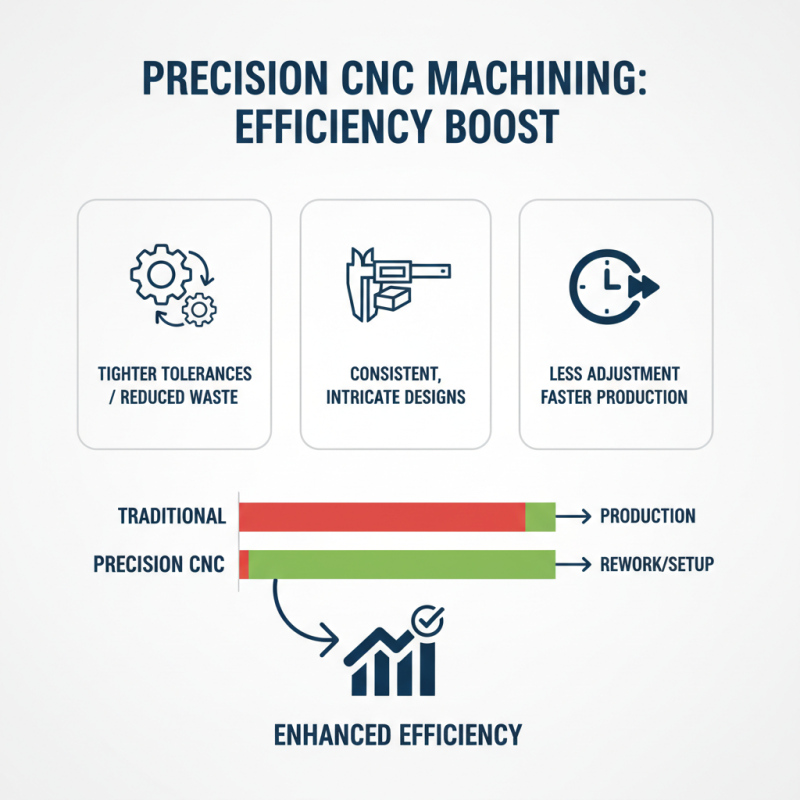

The Role of Precision in CNC Machining for Enhanced Efficiency

Precision in CNC machining plays a crucial role in enhancing efficiency within manufacturing processes. Achieving high precision allows for tighter tolerances, reducing waste and the need for rework. Operators can produce intricate designs with consistency. This means less time spent on adjustments and more focus on production.

Tips for improving precision include regularly calibrating your machines. Check your tools for wear and replace them as needed. Small details like tool sharpness can make a big difference in the final product. Additionally, consider using high-quality materials that fit your specifications. This choice can minimize defects and improve overall outcomes.

Remember, even with precision techniques, mistakes can happen. A small error in setup can lead to larger issues down the line. Always analyze your processes for potential improvements. Take time to audit your workflows. This reflection can unveil areas to enhance, ensuring that you maintain top-notch efficiency in your CNC operations.

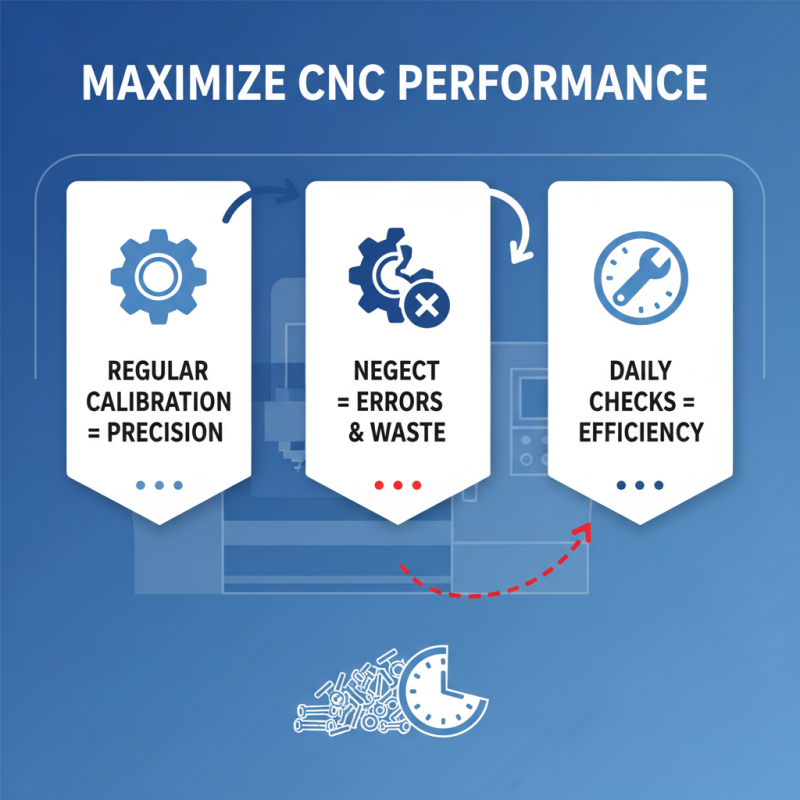

Top Techniques for Maximizing CNC Machine Performance

Maximizing CNC machine performance requires a keen focus on detail and technique. One effective approach is regular calibration. A well-calibrated machine significantly improves precision. Neglecting this can lead to errors, wasted materials, and lost time. Operators should invest time in daily checks to ensure everything is running smoothly.

Another key technique is optimizing tool selection. Choosing the right tool for the material is crucial. For instance, using a dull tool can cause parts to wear unevenly. This not only affects quality but also impacts overall efficiency. Regularly inspect and replace tools as needed to maintain peak performance.

Furthermore, understanding the full capabilities of your CNC machine can unlock hidden efficiencies. Often, operators stick to familiar settings. Exploring different speeds and feeds might seem risky but may yield better results. Experimentation in a controlled way can reveal new avenues for productivity. There's always room for improvement, and sometimes it comes from unexpected places.

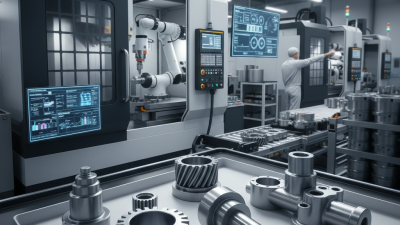

Innovative Tools and Technologies in Precision CNC Manufacturing

Innovative tools and technologies shape the future of precision CNC manufacturing. Automation is a major trend. It reduces manual labor and enhances consistency. Robotic arms perform complex tasks with high accuracy. They work alongside humans, improving operational efficiency. However, reliance on automation poses challenges in programming and maintenance.

3D printing is also revolutionizing manufacturing. It allows for rapid prototyping. Designers can create and test parts quickly. Yet, the technology is still evolving. Material limitations can hinder production quality. Finding the right balance is crucial. Companies must assess the benefits and drawbacks continually.

Smart manufacturing technologies enhance precision CNC processes. Internet of Things (IoT) devices collect essential data. They provide real-time feedback for better decision-making. However, integrating these systems can be complex. Connectivity issues often arise. Companies need to invest time and resources in training. Effective implementation remains a significant challenge.

Top 10 Precision CNC Techniques for Maximum Efficiency in Manufacturing

| Technique | Description | Efficiency Gain (%) | Applied Tools |

|---|---|---|---|

| Adaptive Machining | Real-time adjustments to machining parameters based on sensor data. | 20 | Sensors, Custom Software |

| Multi-axis Machining | Simultaneous machining on multiple axes to reduce cycle time. | 30 | CNC Machines |

| Automation & Robotics | Integration of robots for loading and unloading operations. | 40 | Robotic Arms, Automation Software |

| 3D Printing Integration | Using 3D printing for rapid prototyping and production of parts. | 25 | 3D Printers |

| Tool Path Optimization | Analyzing and refining the tool path for efficiency. | 15 | CAM Software |

| High-Speed Machining | Increasing spindle speeds to enhance material removal rates. | 35 | High-Speed CNC Machines |

| Digital Twins | Virtual models to simulate and optimize manufacturing processes. | 20 | Simulation Software |

| Micro Machining | Precision processing of very small features. | 50 | Micro CNC Machines |

| Laser Cutting/Engraving | Utilizing lasers for precise cutting and engraving. | 45 | Laser Machines |

Best Practices for Implementing CNC Techniques in Production Systems

Implementing precision CNC techniques in production requires careful planning and awareness. Start by assessing your current processes. Identify areas for improvement. Streamline workflows to minimize delays. Effective use of software for scheduling can play a significant role. Real-time data is essential to monitor machine performance and productivity levels.

Training staff is equally vital. Ensure operators understand machine capabilities and limitations. Hands-on training sessions can enhance their skills. Encourage feedback from the team. Sometimes, the most straightforward techniques can yield the best results. Regularly review operational procedures for inefficiencies. Evaluate whether your current tools really meet the production needs.

Maintaining machines is another critical step. Regular inspections help avoid breakdowns. Downtime can lead to significant losses. Allocate resources for repairs and upgrades. Keep a maintenance log to track issues. These practices may seem small, but they contribute to overall efficiency. Continuous improvement is essential in the rapidly evolving manufacturing landscape. Embrace change, but proceed with caution.

Related Posts

-

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

-

Top 5 Advantages of Using Prototype Machined Parts for Efficient Production

-

Why Choosing the Right CNC Parts is Essential for Your Machinery Performance

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

Top 10 CNC Milling Machines for Precision Machining in 2023

-

Exploring the Future of Manufacturing: How CNC Machine Tools Revolutionize Precision Engineering