Top CNC Parts for Precision Manufacturing What You Need to Know?

In the world of precision manufacturing, understanding the significance of CNC parts is crucial. Renowned expert Dr. Samuel Lee once stated, “CNC parts are the backbone of modern manufacturing.” This highlights the importance of quality and precision in these components.

CNC parts come in various types, each vital for different applications. The selection and quality of these parts can greatly affect production efficiency. Manufacturers often face challenges in sourcing the right parts, which can lead to delays. Some might underestimate the impact of a single faulty component.

Moreover, while advancements in technology enhance production capabilities, they also raise expectations for CNC parts. Engineers and manufacturers must stay informed about new innovations. Relying solely on past experiences may hinder progress. Embracing change and reevaluating sourcing strategies are necessary for continuous improvement.

Essential CNC Components for Precision Manufacturing

CNC manufacturing relies on several essential components for precision. The

spindle is a primary part. It holds the cutting tool and rotates it at high speeds. The

quality of the spindle significantly affects the machining accuracy. A poorly calibrated spindle can lead to

rough edges and wasted materials.

Another critical component is the CNC controller. This device interprets

instructions and coordinates movements. An intuitive interface enhances user experience. However, not all

controllers are easy to manage. Many operators spend time troubleshooting and adjusting settings. This can slow

down the production process and increase costs.

Lastly, consider the linear guide rails. They ensure the machine’s parts

move smoothly. If these rails are misaligned or worn, they can cause inaccuracies. Routine maintenance is vital

but often overlooked. Operators should regularly check for wear signs. Neglecting this can lead to bigger issues

down the line.

Attention to these components can improve quality and efficiency in CNC machining.

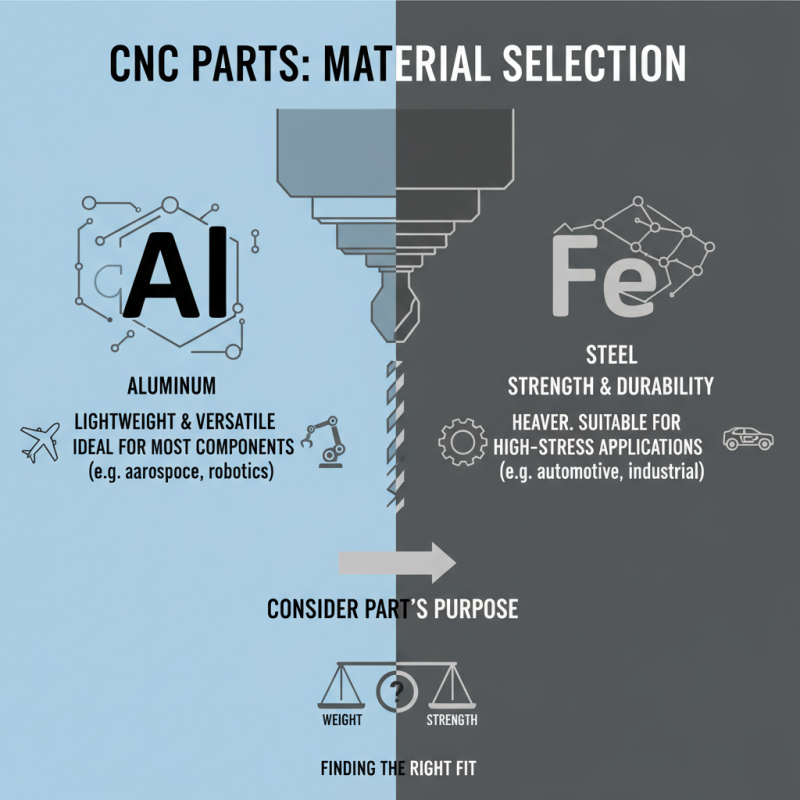

Understanding Material Selection for CNC Parts

When selecting materials for CNC parts, it's vital to consider the part's purpose. Different applications require different materials. For instance, aluminum is lightweight and versatile, making it ideal for many components. On the other hand, steel offers strength but is heavier. Understanding these properties will lead to better decisions.

One often overlooked factor is the machining process. Some materials are easier to work with than others. For example, plastics can be simpler to machine, but they may lack the durability needed in harsh environments. This complexity can lead to mistakes if not properly accounted for.

**Tip:** Always conduct a thorough analysis before selecting materials. Consider the environment where the part will be used. Will it face high temperatures or corrosive substances? These factors greatly affect performance.

Pay attention to cost too. While certain materials may be cheaper initially, they could incur higher costs in the long run if they wear out quickly. A perfect balance between cost and performance is essential.

**Tip:** Don't rush the selection process. Take time to research and analyze different options. Ostensibly small details can make a significant difference in the end product.

Key Specifications to Consider in CNC Manufacturing Parts

When exploring CNC manufacturing parts, several key specifications are vital. Tolerances are critical; parts must meet precise measurements. Typically, a tolerance of ±0.001 inches is common in high-precision industries. For some applications, tighter tolerances of ±0.0001 inches may be necessary. These specifications directly impact the final product's quality and performance.

Material selection also plays a crucial role. Common choices include aluminum, steel, and plastics. Each material has unique properties, affecting durability and weight. For instance, aluminum is lightweight and corrosion-resistant, while steel offers higher strength. Choosing the right material can lead to significant improvements in product lifespan and efficiency.

Surface finish should not be overlooked. It influences both aesthetics and functionality. Reports indicate that a better surface finish can reduce friction and wear. Typical finishes range from Ra25 to Ra10 micrometers for various applications. Finding the balance between visual appeal and performance is often challenging. Complexity in designs may require compromising on certain finishes to keep costs in check or meet deadlines.

Top CNC Parts for Precision Manufacturing - Key Specifications to Consider in CNC Manufacturing Parts

| Part Name | Material | Tolerance (mm) | Surface Finish | Applications |

|---|---|---|---|---|

| CNC Machined Parts | Aluminum 6061 | ±0.05 | Anodized Finish | Aerospace, Automotive |

| Spindle | Stainless Steel | ±0.01 | Polished | Industrial Machines |

| Gear | Plastic Nylon | ±0.03 | Natural Finish | Robotics, Automotive |

| Bracket | Mild Steel | ±0.1 | Powder Coated | Construction, Machinery |

Advantages of Using High-Quality CNC Parts

High-quality CNC parts play a crucial role in precision manufacturing. These parts ensure better accuracy and improved performance. According to industry reports, using top-tier components can increase machining precision by up to 30%. This is significant in sectors like aerospace and medical devices, where tolerances are tight.

The durability of CNC parts also affects production efficiency. Studies indicate that high-quality components can extend the lifespan of machinery. For example, machines using premium CNC parts may last 20% longer. Lower maintenance costs lead to better profit margins. However, it’s essential to recognize that not all manufacturers can access the best materials, impacting their overall output quality.

Using high-grade CNC parts builds a reputation over time. Clients often prefer suppliers who provide consistent, high-quality products. Not all suppliers meet these standards, and some may compromise on quality. Choosing the right partner is essential but can be challenging. This inconsistency in availability and pricing can lead to frustrations for many manufacturers. Quality control should not be overlooked.

Maintenance Tips for Extending CNC Part Lifespan

Maintaining CNC parts is crucial for ensuring longevity and precision in manufacturing. Regular cleaning is essential. Dust and debris can accumulate, impacting performance. Using a soft cloth helps in removing particles without causing scratches. Inspect moving parts frequently. Look for signs of wear and tear. Sometimes, you may overlook minor issues, but they can lead to bigger problems.

Lubrication plays a vital role in keeping CNC machines running smoothly. Different parts require specific lubrication techniques. Ensure you use the right type of lubricant. Over-lubrication can attract dirt, creating a messy buildup. It’s a fine balance. Check levels regularly, and avoid neglecting this part of maintenance.

Cooling systems also need attention. They prevent overheating, which can damage vital components. Clean the coolant lines and check for blockages. Sometimes, users forget about proper coolant concentration, leading to inefficiencies. It’s easy to get caught up in production and skip this step. However, maintaining the right conditions is necessary for optimal operation.

Related Posts

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

2026 Top Trends in CNC Parts for Precision Engineering and Manufacturing?

-

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

-

Top 10 Precision CNC Techniques for Maximum Efficiency in Manufacturing?

-

How to Achieve Precision with Fast CNC Machining Techniques?

-

Top 10 Best CNC Machining Prototyping Services for Your Projects?