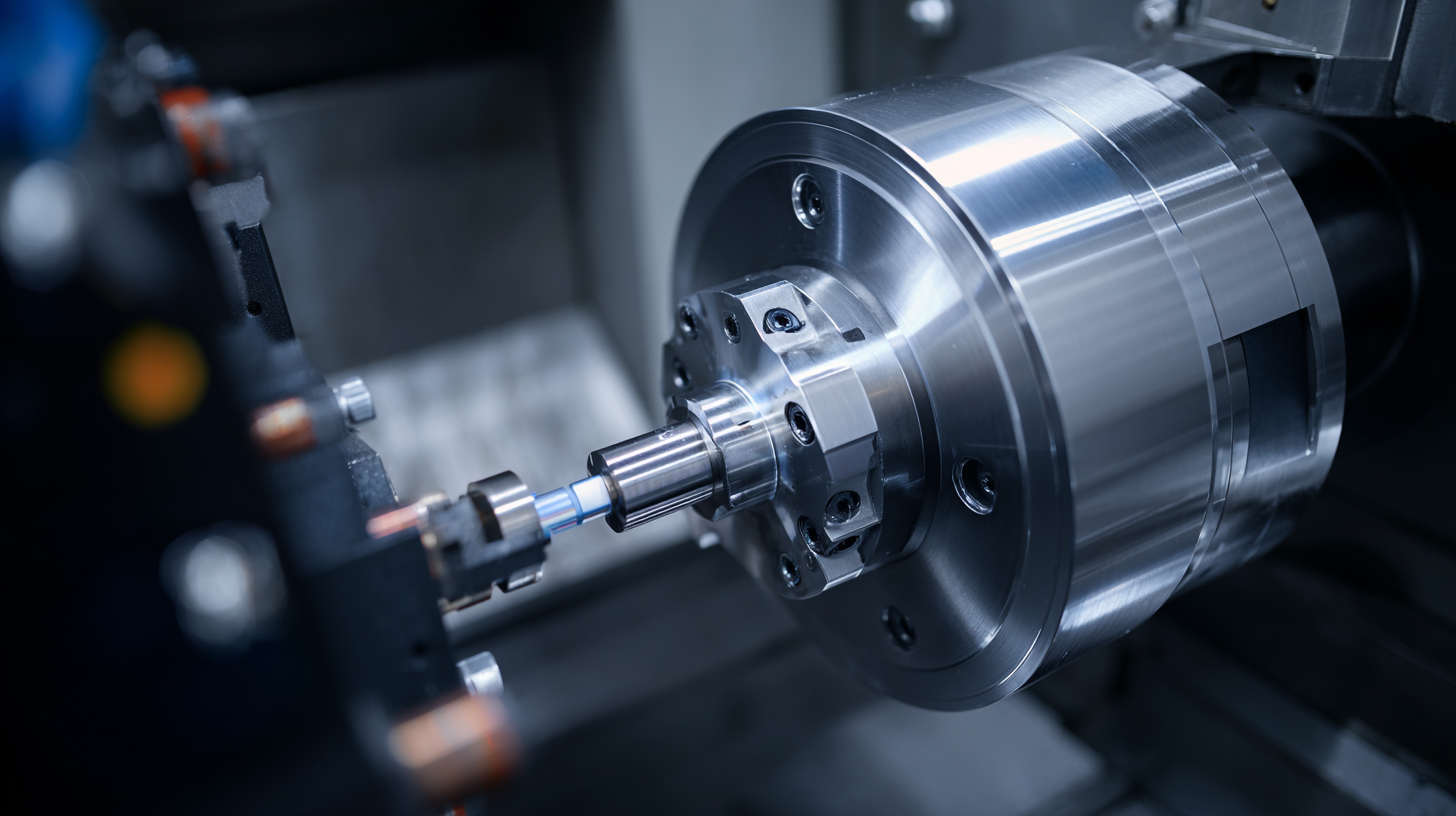

Exploring the Future of Precision Engineering with CNC Turning Machines

In the rapidly evolving landscape of manufacturing, the precision engineering sector has witnessed a remarkable transformation, largely attributed to the advent of sophisticated technologies such as the CNC turning machine. These machines, which utilize computer numerical control to automate the turning process, offer unparalleled accuracy and efficiency in producing complex geometries and intricate components. As industries continue to demand higher precision and faster production rates, the role of CNC turning machines becomes increasingly crucial.

This exploration delves into the future of precision engineering, highlighting advancements in CNC technology and its implications for various sectors, including automotive, aerospace, and medical manufacturing. By understanding the capabilities and potential of CNC turning machines, we can better appreciate their impact on innovation and quality in precision engineering, ultimately paving the way for smarter manufacturing solutions.

The Role of CNC Turning Machines in Advancing Precision Engineering

CNC turning machines are increasingly recognized as pivotal players in the realm of precision engineering. As industries strive for higher accuracy and efficiency, these machines have demonstrated their ability to meet the stringent demands of modern manufacturing. The projected growth of the CNC machine market, expanding from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, underscores the increasing reliance on these technologies to advance precision engineering capabilities.

For manufacturers, investing in CNC turning machines not only enhances production quality but also optimizes operational efficiency. Tips for maximizing the benefits of these machines include regular maintenance to ensure precision over time, investing in skilled operators who can fully leverage the technology, and utilizing advanced software for design and simulation to predict potential issues before production begins.

Furthermore, the expected 9.9% annual growth rate highlights the importance of innovation in this field. Companies must continually adapt and integrate new features into their CNC turning machines to stay competitive. By focusing on innovative practices and embracing continuous improvement, organizations can solidify their position in the rapidly evolving landscape of precision engineering.

Innovations Driving the Evolution of CNC Technology

The landscape of CNC technology is undergoing remarkable transformations fueled by innovations that prioritize efficiency and sustainability. As industries increasingly integrate artificial intelligence and robotics into their machining processes, we witness a significant shift toward precision engineering. These advancements not only streamline operations but also enhance the precision of the finished products, making CNC machines indispensable in sectors ranging from automotive to aerospace.

A noteworthy example of this evolution is the introduction of next-generation CNC routers that incorporate AI-driven features, optimizing productivity while minimizing waste. The global market for CNC machine tools is poised for substantial growth, projected to expand by billions as the demand for high-precision and multi-axis machining centers rises. This trend emphasizes the critical role that innovative technologies play in driving the future of manufacturing, setting the stage for a new era of sophisticated and sustainable machining solutions.

Exploring the Future of Precision Engineering with CNC Turning Machines

The chart above illustrates the adoption rate of CNC turning machines from 2019 to 2023, showcasing the rapid growth and innovation in precision engineering technology.

Integrating Digital Tools for Enhanced CNC Turning Performance

The integration of digital tools into CNC turning machines is revolutionizing precision engineering by elevating productivity and accuracy. According to a report by MarketsandMarkets, the global CNC machine market is anticipated to grow from $69.3 billion in 2020 to $100.5 billion by 2025, driven by advancements in digital technology. These tools, ranging from predictive maintenance software to advanced simulation systems, enable manufacturers to optimize machining processes in real time, reducing errors and enhancing product consistency.

Tips for improving performance with digital tools include implementing real-time monitoring systems, which allow for immediate adjustments during the turning process. Moreover, utilizing CAD/CAM software can significantly decrease setup times and enhance design accuracy. It’s crucial for operators to stay updated on the latest digital solutions to leverage the full potential of their CNC machines.

Additionally, integrating IoT capabilities into CNC turning setups facilitates the collection of valuable data, which can be analyzed for continuous improvement. A recent analysis indicated that companies employing digital transformation strategies in their manufacturing saw an average productivity increase of 20%. Embracing this digital shift not only streamlines operations but also positions businesses competitively in the fast-evolving landscape of precision engineering.

Sustainability in Precision Engineering: The Impact of CNC Machines

Sustainability is becoming a critical consideration in precision engineering, particularly with the advent of CNC turning machines. According to a recent report by the

International Journal of Advanced Manufacturing Technology, CNC machines can reduce waste generation by approximately 30% compared to traditional machining methods. This is due in part to their high levels of precision, which minimize the material removed during the machining process. As manufacturers increasingly prioritize sustainability, the integration of CNC technology provides a pathway to achieving both efficiency and environmental responsibility.

Furthermore, the energy efficiency of CNC turning machines contributes significantly to sustainable practices in the industry. A study published in the Journal of Cleaner Production indicates that modern CNC systems consume up to 40% less energy than their predecessors while delivering greater productivity. This reduction in energy consumption not only lowers operational costs but also decreases the overall carbon footprint of manufacturing processes. As the industry shifts towards greener practices, the role of CNC machines in facilitating sustainable precision engineering becomes ever more vital.

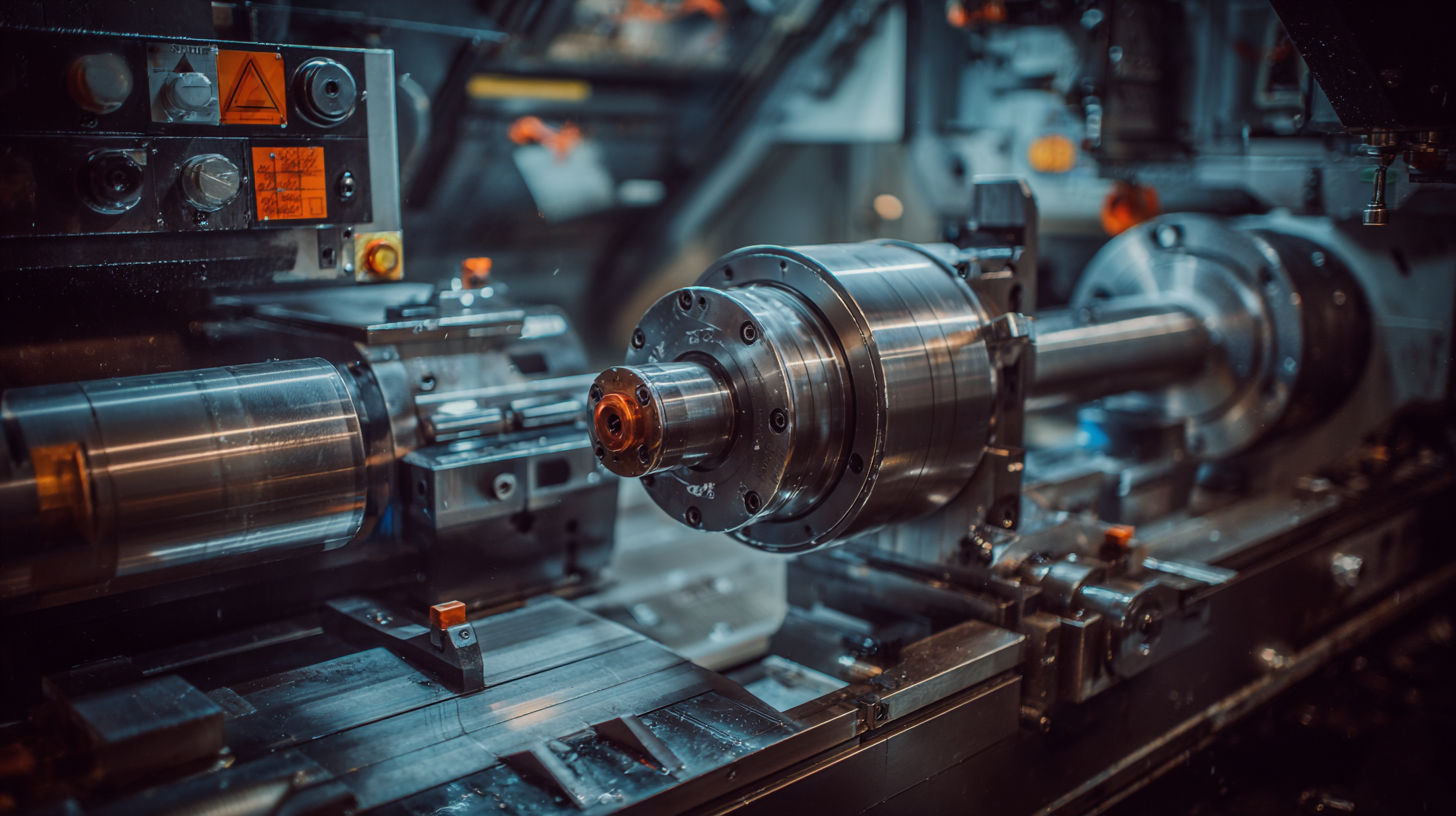

Future Trends in CNC Turning: Automation and Smart Manufacturing

The landscape of CNC turning is rapidly transforming, driven by advancements in automation and smart manufacturing technologies. As the global CNC machine market continues to expand, with a projected valuation reaching USD 101.22 billion, manufacturers are increasingly adopting automated solutions to enhance production efficiency and precision. This shift towards automation is not only focused on improving productivity but also on minimizing human error, ensuring that highly intricate designs can be executed with utmost reliability.

The integration of smart manufacturing concepts into CNC turning operations is also notable. The utilization of IoT (Internet of Things) technologies and sophisticated CNC controller systems is paving the way for real-time monitoring and data-driven decision-making. These innovations empower manufacturers to optimize machining processes, predict maintenance needs, and achieve higher flexibility in production lines. As industries embrace these future trends, the CNC retrofit kits market is poised for significant growth, allowing even legacy machines to benefit from modern automation enhancements.