What is a CNC Mill and How Does It Work?

A CNC mill is an essential tool in modern manufacturing. It uses computer-controlled machinery to shape materials. However, many still wonder how it truly works. A CNC mill operates by precisely removing material from a workpiece. This process allows for complex and accurate designs.

Understanding a CNC mill involves recognizing its components. The machine typically includes a rotating spindle, which holds the cutting tool. It moves along different axes to shape the material. Mistakes during setup can lead to errors in production. Operators must pay close attention to details.

While CNC mills increase efficiency, they also require skilled operators. Knowledge about programming and maintenance is crucial. A small error could result in wasted materials and time. Reflecting on these challenges highlights the importance of training in CNC technology.

What is a CNC Mill?

A CNC mill is a machine that uses computer numerical control to automate the process of machining materials. This technology allows for precision cutting, drilling, and engraving on various substrates like metal, wood, and plastics. According to a report by the International Federation of Robotics, the global market for CNC machines is expected to grow by over 7% annually. This reflects a strong interest in automation and advanced manufacturing techniques.

CNC mills operate based on coded instructions. The computer interprets each command to manipulate the movement of the mill. However, programming these machines can be complex. Operator errors can lead to production issues. Additionally, not all materials respond well to CNC milling, which can result in unexpected wear on tools or poor-quality output. It's crucial for operators to have adequate training and experience.

The benefits of CNC milling include speed and precision. Production times can be significantly reduced when compared to traditional methods. However, initial setup costs can be high. Many small businesses shy away from investing in CNC technology due to these costs. Owning and maintaining CNC equipment also requires a consistent commitment to training and updates to software, which can be daunting for some manufacturers.

What is a CNC Mill and How Does It Work?

| Dimension | Specification |

|---|---|

| Working Area | 2000 x 1000 mm |

| Max Spindle Speed | 24000 RPM |

| Tool Type | End Mill |

| Material Compatibility | Aluminum, Steel, Plastic |

| Control System | G-code |

| Operating Software | CAD/CAM Software |

| Power Requirement | 3-phase, 220V |

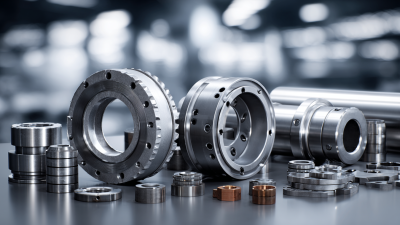

Key Components of a CNC Mill

CNC mills are essential tools in manufacturing. They rely on precise engineering to operate effectively. Key components define their performance. The primary parts include the spindle, tooling, and the control system.

The spindle holds the cutting tool. A robust spindle ensures durability. This component rotates at different speeds. Reports show that optimal spindle speeds can range from 5,000 to 30,000 RPM. This range allows for various materials to be machined. However, excessive speeds can lead to tool wear. Operators must balance speed and material type carefully.

The tooling is critical for effective machining. Different tools serve specific functions. It is not uncommon to switch between end mills, drills, and taps. Each tool has a unique design for its task. Incorrect selections can lead to poor finishes or damage. Control systems play a pivotal role in accuracy. They interpret design files and guide machine movements. Modern systems often utilize G-code. Yet, programming errors can result in costly mistakes. Each component matters, and their interplay affects overall productivity.

Understanding the CNC Milling Process

CNC milling is essential in modern manufacturing. The process uses computer-controlled machines to create parts from various materials. Typically, it involves subtracting material from a solid block to achieve precise shapes and dimensions. Data suggests that the CNC milling market is projected to grow at a CAGR of around 6% from 2021 to 2028. This indicates high demand across different sectors, including aerospace and automotive.

During CNC milling, the machine follows a programmed path. This path is defined by a series of coordinated movements. It’s fascinating how this automation reduces human error and increases efficiency. However, some operators struggle with programming complexities. This could lead to mistakes if not addressed properly. Reports show that over 30% of CNC machine failures stem from software issues. Operators must undergo training for both machine and software.

Moreover, the material choice plays a critical role in the milling process. Materials like aluminum, steel, and plastics react differently to milling techniques. For instance, aluminum can be milled faster than steel, but it requires careful handling to prevent damage. In some cases, operators may ignore this, leading to frequent tool wear. Such oversights can result in costly downtime, highlighting the need for better training and awareness in the field.

CNC Mill Operation Overview

This chart illustrates key operational parameters for CNC milling, including cutting speed, feed rate, depth of cut, and tool diameter. Understanding these parameters is crucial for optimizing the CNC milling process.

Applications of CNC Milling in Various Industries

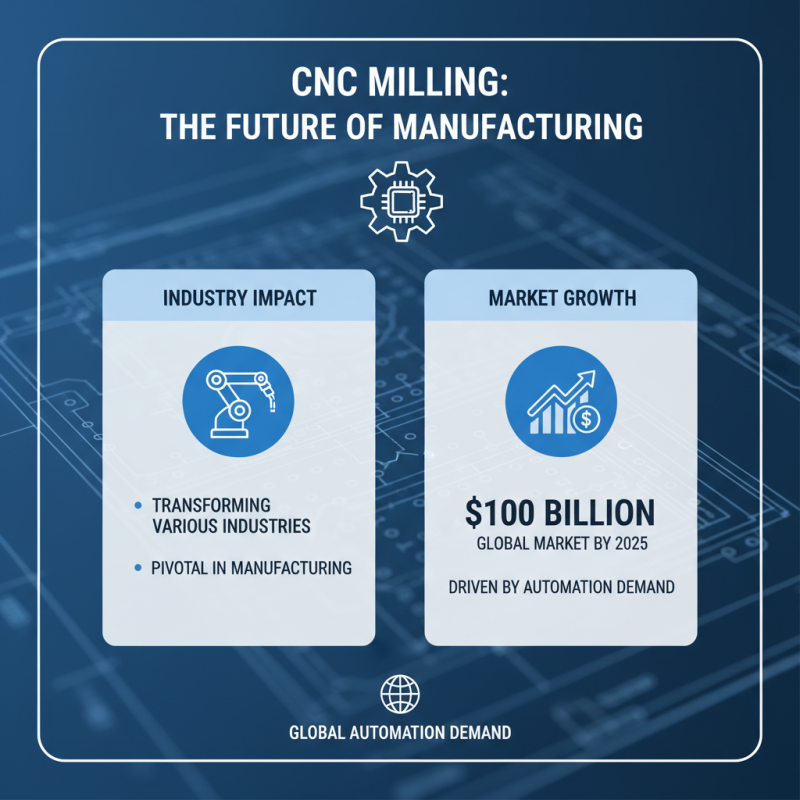

CNC milling is transforming various industries. In manufacturing, it plays a pivotal role. The global CNC milling market is projected to reach $100 billion by 2025, driven by increased automation demands.

In the automotive sector, CNC mills produce components with high precision. For example, parts for engines and transmissions are often created using this technology. A report by MarketsandMarkets indicates a 7% annual growth in CNC machining for automotive applications. Consistency in quality reduces waste and enhances safety, but it can still lead to challenges in material limitations.

Aerospace is another industry benefiting significantly. CNC milling is utilized to manufacture lightweight components that meet stringent regulations. According to Aerospace & Defense News, about 50% of aerospace parts are now made using CNC processes. While this improves efficiency, there are ongoing concerns about supply chain disruptions. Manufacturers often encounter delays, impacting project timelines. Despite its advantages, achieving an optimal balance between speed and quality remains a challenge.

Advantages of Using CNC Mills Over Traditional Milling Methods

CNC mills have revolutionized the milling process. They offer precision that traditional methods often lack. CNC stands for Computer Numerical Control. This technology allows for automated cutting, resulting in consistent product quality. With CNC mills, you can achieve intricate designs that manual mills may struggle with. This is particularly useful in industries requiring high precision.

Another advantage is speed. CNC mills can work much faster than manual versions. A job that takes hours on a traditional mill may only require minutes with CNC. They also reduce the chances of human error. However, there is a learning curve. Operators must understand programming and machine operation. This can be daunting for some.

CNC mills require maintenance, too. Without proper care, they may not perform optimally. Despite these challenges, the advantages are significant. They enhance productivity and quality in the manufacturing process. Embracing CNC technology can be a game-changer for many businesses.

Related Posts

-

2026 Best CNC Milling Parts for Precision Engineering?

-

Exploring the Future of Precision Engineering with CNC Turning Machines

-

Unlocking Innovation: The Vital Role of Machined Parts in Modern Manufacturing Advances

-

Top 10 Benefits of Using Prototype Machined Parts for Your Projects

-

2025 Guide: How to Choose the Best Milling Machine Tools for Your Workshop

-

Top 10 CNC Milling Machines for Precision Machining in 2023