Maximizing Efficiency and Precision in Manufacturing with CNC Lathe Technology Insights and Trends

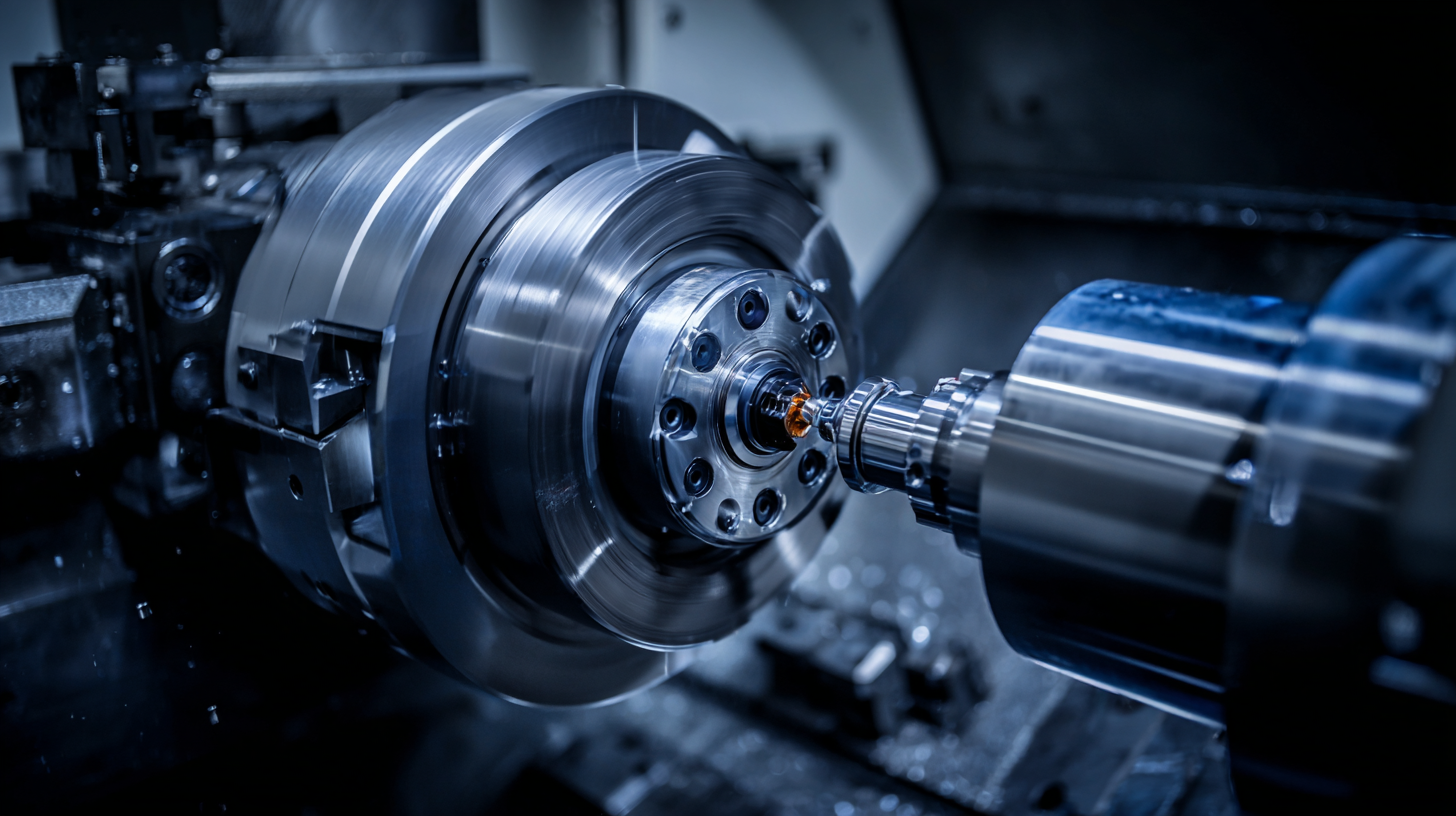

In today's fast-paced manufacturing landscape, the pursuit of efficiency and precision has never been more critical. One of the most transformative advancements in this realm is the implementation of CNC lathe technology. CNC, or Computer Numerical Control, revolutionizes the way machining processes are executed, enabling manufacturers to produce intricate parts with unparalleled accuracy and speed. As industries continue to demand tighter tolerances and faster turnaround times, CNC lathes emerge as essential tools that maximize productivity and minimize waste.

In today's fast-paced manufacturing landscape, the pursuit of efficiency and precision has never been more critical. One of the most transformative advancements in this realm is the implementation of CNC lathe technology. CNC, or Computer Numerical Control, revolutionizes the way machining processes are executed, enabling manufacturers to produce intricate parts with unparalleled accuracy and speed. As industries continue to demand tighter tolerances and faster turnaround times, CNC lathes emerge as essential tools that maximize productivity and minimize waste.

The integration of CNC lathe technology not only enhances the precision of machining operations but also offers insights into trends that shape the future of the manufacturing sector. With the ability to automate complex tasks and reduce human error, companies are increasingly relying on CNC lathes to streamline their production lines. This shift allows for greater flexibility in design and scalability in production, further solidifying the CNC lathe's role as a cornerstone of modern manufacturing.

As we delve into the latest insights and trends surrounding CNC lathe technology, it becomes evident that embracing these innovations will be pivotal for manufacturers striving to maintain a competitive edge in the market. By understanding the capabilities and future potential of CNC lathes, companies can unlock new opportunities for efficiency and precision, ultimately leading to enhanced operational outcomes.

Revolutionizing Manufacturing: The Role of CNC Lathe Technology

CNC lathe technology is fundamentally revolutionizing the manufacturing landscape by offering enhanced precision and efficiency. As industries increasingly embrace advanced machine tools, the integration of Digitalization and automation, alongside innovations such as AI and IoT, is transforming how manufacturing processes operate. The capabilities of CNC machines enable manufacturers to produce intricate parts with remarkable accuracy, minimizing waste and optimizing resource utilization. This shift is crucial, particularly in response to labor shortages, with innovative solutions like autonomous microfactories setting the stage for a new era of manufacturing.

Moreover, the CNC machine tools market is projected to experience significant growth, driven by the rising demand for high-precision and multi-axis machining centers. Emerging technologies are redefining the market landscape, pushing the boundaries of what is possible in precision manufacturing. Companies that leverage advanced CNC programming techniques are finding ways to streamline operations and reduce lead times, thereby enhancing their competitiveness in a rapidly evolving industrial ecosystem. As manufacturing continues to adapt to these changes, the role of CNC lathe technology remains pivotal, positioning it as a cornerstone of modern manufacturing excellence.

Maximizing Efficiency and Precision in Manufacturing: CNC Lathe Technology Trends

This bar chart illustrates the percentage increase in manufacturing efficiency and precision reported by manufacturers adopting CNC lathe technology over the past five years. The data highlights key trends in productivity gains across different sectors.

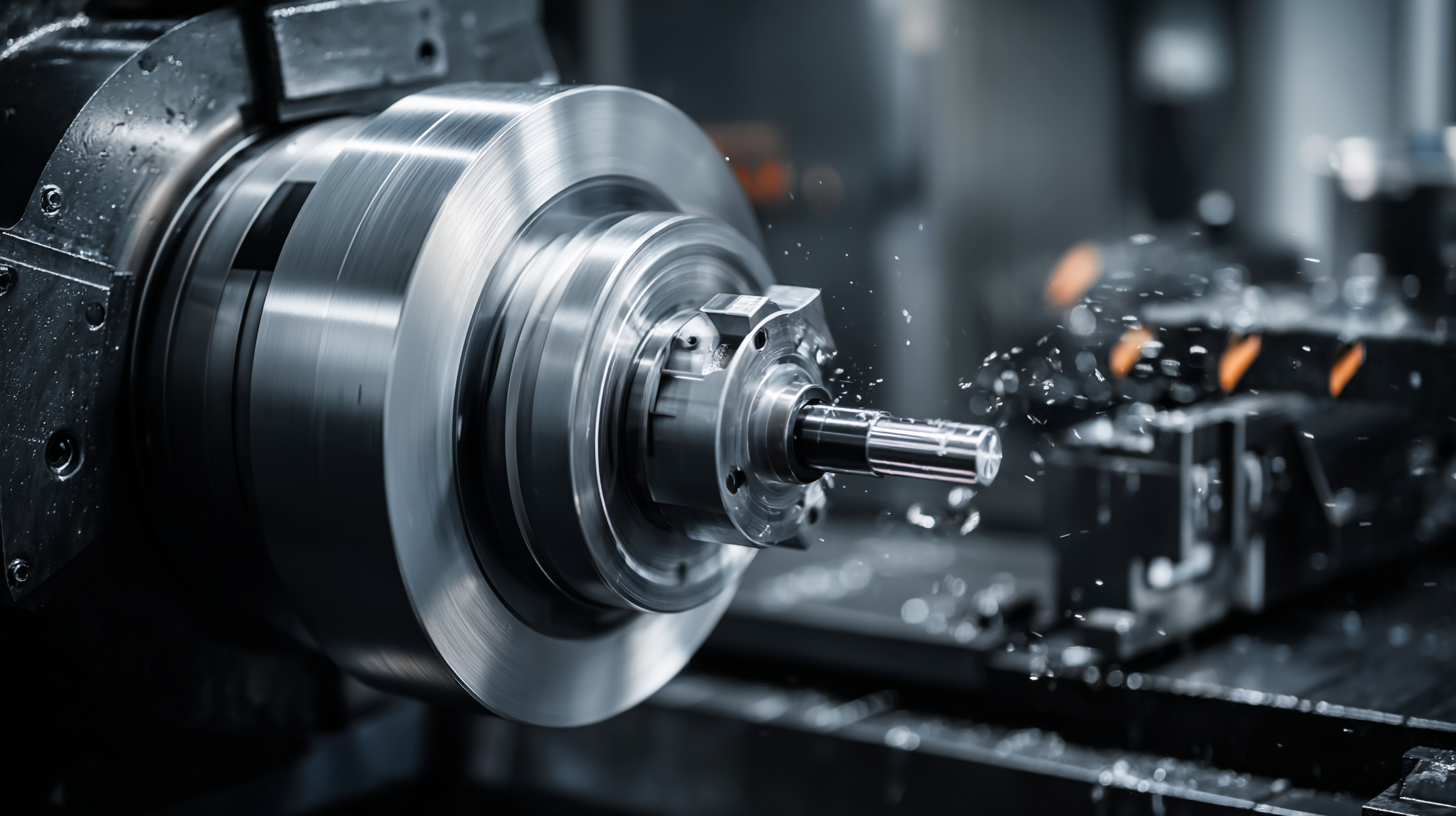

Enhancing Production Workflow with CNC Lathe Automation

The implementation of CNC lathe automation has become a transformative force in modern manufacturing, markedly enhancing production workflows across various sectors. By integrating CNC technology into manufacturing processes, companies can achieve unprecedented levels of precision and efficiency. This automation not only minimizes human error but also allows for rapid adjustments and scalability in operations, which are crucial in today’s fast-paced market.

Recent advancements, such as real-time NC access tools and cloud-based monitoring, further elevate the capabilities of CNC lathe systems. These innovations provide manufacturers with the tools needed for data visualization and seamless integration with existing monitoring systems. The result is a significant reduction in downtime and an increase in overall productivity. As the global market for precision turned products is projected to expand significantly in the coming years, embracing these automated solutions will be essential for businesses aiming to stay competitive and agile in their manufacturing endeavors.

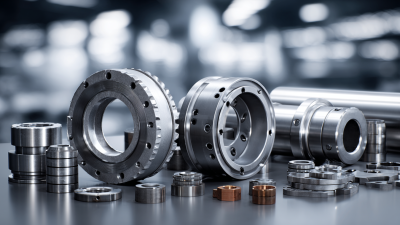

Key Trends Shaping the Future of CNC Lathe Precision

The CNC lathe technology is transforming manufacturing processes by enhancing precision and efficiency across various industries. Key trends shaping the future of CNC machining include the rise of automated calibration systems. These systems streamline the maintenance of measurement accuracy, reducing the dependence on manual adjustments and minimizing human error. As a result, manufacturers can achieve greater consistency in their output, vital for meeting the increasing demand for high-quality products.

Moreover, the integration of AI and robotics in CNC machining is expected to revolutionize traditional practices. These technologies not only improve productivity but also facilitate complex design capabilities that were previously unattainable. The market for CNC machines is projected to reach USD 170.4 billion by 2033, demonstrating a robust growth rate of 9.80% annually. This surge reflects the industry's increasing adoption of digital manufacturing technologies, which play a crucial role in enhancing operational efficiency.

**Tip:** Investing in advanced automated systems can significantly enhance your manufacturing accuracy. Regular training on these technologies will ensure your team can effectively utilize the latest advancements. Additionally, keeping abreast of market trends can help identify opportunities for upgrading your machining processes.

Tips for Optimizing CNC Lathe Performance and Efficiency

The landscape of manufacturing is rapidly evolving, driven by cutting-edge CNC lathe technologies. The global CNC machine market is anticipated to expand significantly, with a projected growth from $101.22 billion in 2025 to $195.59 billion by 2032, at a compound annual growth rate (CAGR) of 9.9%. This growth highlights the increasing reliance on CNC technology to improve precision and efficiency in manufacturing processes.

To optimize CNC lathe performance and efficiency, manufacturers can adopt several strategies. One effective approach is understanding and adjusting gear ratios, which plays a crucial role in optimizing both performance and productivity. By fine-tuning gear ratios, manufacturers can achieve better torque and speed balance, enhancing overall machine efficiency.

Moreover, leveraging advanced technologies such as AI and deep learning algorithms can further maximize machining capabilities. Recent studies on the machinability of novel materials like LM25 aluminum alloy reinforced with vanadium carbide have revealed the potential of integrating analytical modeling and neural networks to refine machining processes. Embracing these innovative approaches will not only enhance efficiency but also position manufacturers at the forefront of the evolving industry landscape.

Integrating Smart Technologies with CNC Lathe Operations

Integrating smart technologies into CNC lathe operations represents a pivotal shift in manufacturing efficiency and precision. As factories increasingly adopt digital solutions, the result is a marked improvement in productivity across various industries. This integration not only streamlines processes but also provides manufacturers with data-driven insights that enable better decision-making. For instance, machine monitoring systems can transform turning machine data into actionable intelligence, driving substantial productivity gains and enhancing sustainability efforts.

Tips: To maximize the benefits of smart technologies in CNC operations, consider implementing real-time machine monitoring. This approach allows for the immediate identification of inefficiencies and potential issues before they escalate. Additionally, investing in training for your workforce on these new technologies will ensure seamless integration and optimal utilization.

Furthermore, the adoption of AI in manufacturing processes, as seen with recent state grants, exemplifies the importance of staying ahead in an evolving market. By leveraging intelligent robotics and AI, companies can not only enhance their operational capabilities but also secure their competitiveness in the manufacturing landscape. Continuous investment in these technologies will be crucial for future success.

Related Posts

-

Exploring the Future of Manufacturing: How CNC Machine Tools Revolutionize Precision Engineering

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

-

Exploring the Future of Precision Engineering with CNC Turning Machines

-

Unlocking Innovation: The Vital Role of Machined Parts in Modern Manufacturing Advances

-

Understanding the Benefits of Large Part CNC Machining for Precision Manufacturing