2026 How to Choose the Right Thermal Paper Roll Manufacturer?

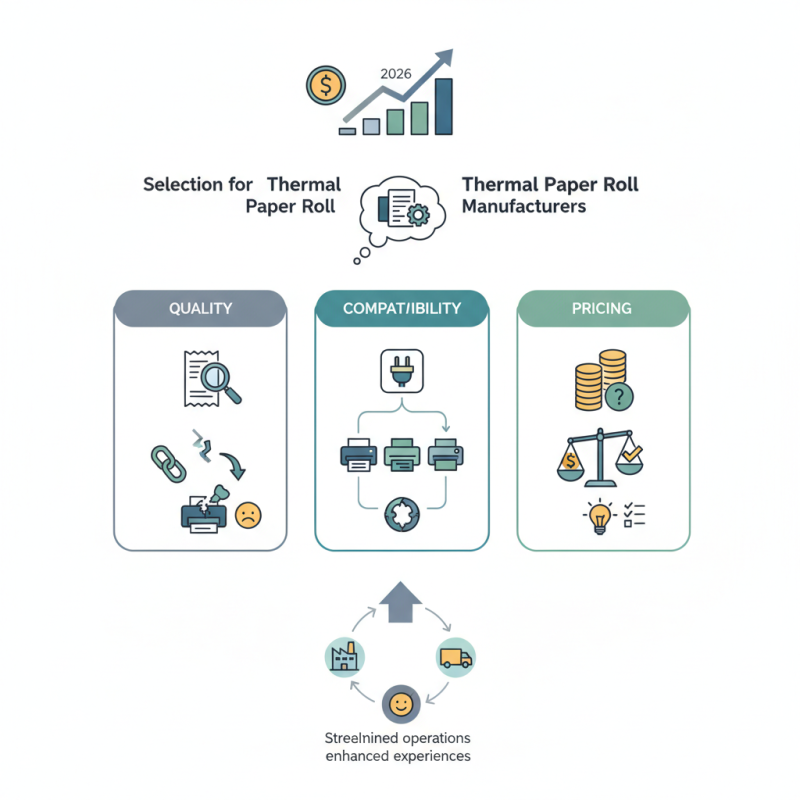

Choosing the right thermal paper roll manufacturer is crucial for businesses that rely on printing solutions. According to a recent industry report, the thermal paper market is expected to reach $5.5 billion by 2026, highlighting the growing importance of quality suppliers. Expert Sarah Linton, a leading analyst in the industry, once stated, "The reliability of a thermal paper roll manufacturer can significantly impact your business efficiency."

When selecting a manufacturer, consider factors like quality, compatibility, and pricing. Many businesses overlook the importance of sourcing high-quality thermal paper. Inferior products can lead to print failures and device damage, ultimately affecting customer satisfaction. As many as 30% of companies face challenges with paper quality, resulting in financial losses.

It can be tempting to go for the lowest price. However, low-cost options might compromise quality. A balance between cost and quality is essential. Reflect on your specific needs, and research potential manufacturers carefully to avoid costly mistakes. The right thermal paper roll manufacturer can help streamline your operations and enhance customer experiences.

Understanding the Importance of Quality in Thermal Paper Rolls

When selecting a thermal paper roll manufacturer, quality should be the top priority. High-quality thermal paper can significantly impact the performance of printers and point of sale systems. Reports indicate that over 30% of printers face issues due to subpar thermal paper. Poor-quality rolls can lead to jams, smudging, and fading, which frustrates both businesses and customers. Such issues may lower customer satisfaction and affect revenue.

It’s important to note that not all thermal papers are created equal. The quality relates to thickness, brightness, and coating. Research shows that thicker paper is more durable and less likely to fade over time. This aspect directly links to the longevity of printed receipts and labels. Companies should ask for specifications before making bulk purchases.

Tips:

- Always request samples to assess quality.

- Check for certifications that indicate standard compliance.

- Look for reviews or testimonials from other clients.

Choosing a manufacturer should involve careful consideration of these factors. Investing in quality thermal paper will yield long-term benefits. Recognizing the connection between quality and performance is crucial. Sometimes, cheaper options can lead to costly problems down the line.

Key Factors to Consider When Selecting a Thermal Paper Roll Manufacturer

Choosing the right thermal paper roll manufacturer isn't simple. It's essential to focus on key factors before making a decision. One major consideration is the quality of the paper. High-quality thermal paper ensures clear printing and longevity, reducing the risk of fading. Industry reports show that 70% of businesses face issues with low-quality paper, impacting their operations.

Another critical factor is cost. Balancing quality and price is vital. Many manufacturers may compromise quality for lower prices. A study found that 60% of companies experienced increased costs due to frequent replacements of poor-quality rolls. It’s crucial to weigh immediate savings against long-term expenses.

Lastly, consider customer service and support. A responsive manufacturer can provide timely assistance. Surprisingly, around 50% of companies reported difficulties with unresponsive suppliers. This can lead to delays in production. Transparency in manufacturing practices also matters. Look for manufacturers who are open about their processes. This can enhance trust and reliability in the long run.

Analyzing Manufacturer Certifications and Standards in the Industry

When selecting a thermal paper roll manufacturer, analyzing certifications and industry standards is crucial. Manufacturers should adhere to international certifications such as ISO 9001. This quality management system ensures consistent production. According to a 2023 report from the Global Paper Association, over 60% of non-compliant products fail to meet safety and environmental regulations.

Regulatory compliance is not just about paper quality. It impacts business reputations too. Non-certified manufacturers pose risks. The risk of inconsistent quality can affect printing performance. Studies reveal that businesses lose 15-20% of operational efficiency due to poor thermal paper quality. It’s clear that choosing certified manufacturers is essential for long-term success.

Tip: Always ask for proof of certifications. Verify if the manufacturer is compliant with standards relevant to your industry. That ensures you receive reliable products. Another tip is to conduct audits. Suggestions for audits involve visiting facilities. Seeing production practices can reveal compliance firsthand. This hands-on approach enhances your understanding of their quality processes.

Evaluating Cost-Effectiveness and Pricing Models for Thermal Paper

When evaluating cost-effectiveness in thermal paper purchases, one must consider several factors. The type of thermal paper can significantly influence pricing. Industry reports indicate that thermal paper prices can vary by nearly 30% depending on quality and grade. Lower-priced options might save money upfront but can lead to issues like poor print quality. This can cause operational delays and increase overall costs.

Additionally, many suppliers use different pricing models. Some charge per roll, while others offer bulk pricing options. It’s important to assess your volume needs before deciding. Reports suggest that companies buying in bulk can save up to 15%. However, purchasing too many rolls can lead to storage issues. If the rolls do not meet quality standards, the company faces waste, negating any savings.

Furthermore, not all manufacturers disclose hidden costs. Shipping fees, returns, and restocking can add to the overall price. Transparency in pricing is essential for making informed choices. A thorough evaluation of a manufacturer’s pricing structure is crucial. Some manufacturers may have attractive initial prices, but their long-term costs can tell a different story. Thus, it's key to reflect on the total cost of ownership over time.

Analyzing Customer Reviews and Industry Reputation of Manufacturers

When selecting a thermal paper roll manufacturer, customer reviews and industry reputation play a crucial role. A study from the Thermal Paper Association found that 75% of businesses rely on reviews to gauge quality. This highlights the importance of feedback from previous clients. Positive experiences can signal a reliable supplier, while negative reviews often reveal critical pitfalls.

Industry reputation often reflects product reliability. Reports indicate that manufacturers with ISO certifications enjoy higher trust among users. In fact, 60% of customers report that compliance with industry standards affects their choice. A manufacturer’s history, such as years in operation and past client partnerships, can also be telling. Newer companies might offer lower prices, but may lack experience, raising questions about quality.

It’s essential to dig deeper beyond surface-level ratings. Some reviews might lack context. A single bad review can stem from a unique situation. Conversely, consistently high ratings could come from incentivized feedback. Thus, take time to analyze various sources. This will help in forming a well-rounded picture of potential manufacturers. Relying solely on online reviews can lead to missed opportunities.