How to Choose the Right CNC Machine Tools for Your Business Needs?

Choosing the right CNC machine tools is essential for any manufacturing business. These tools play a critical role in production efficiency and product quality. However, with numerous options available, the selection process can become overwhelming.

It's important to assess your specific business needs. Consider the types of materials you will work with. Think about the complexity of your designs. Your budget also plays a significant role in decision-making. Investing in CNC machine tools that suit your operations can yield significant returns over time.

Misjudgments can lead to costly errors. Some businesses may opt for less suitable machines, resulting in poor performance. Reflecting on past choices can guide future decisions. Understanding your requirements will help narrow down the options and find the perfect fit. Selecting the right CNC machine tools is not just about features; it’s about aligning them with your goals.

Understanding the Different Types of CNC Machine Tools Available

Choosing the right CNC machine tools can be daunting. There are several types available, each suited for different applications. For instance, CNC milling machines are versatile and used for cutting complex shapes. They can handle various materials like metal and plastic. On the other hand, CNC lathes excel in producing cylindrical parts, offering smooth finishes.

Another option is CNC routers. These are great for softer materials, such as wood and composites. They allow for intricate designs and are commonly used in furniture production. When considering options, it’s crucial to analyze the specific needs of your business. Not every machine fits every purpose. Some may require more setup time, impacting productivity.

Remember that maintenance is vital. Neglecting this aspect could lead to costly downtimes. Evaluate the support available for each type. Check if the learning curve is manageable for your team. Balancing quality and cost can be challenging. It may require adjustments to your initial choice later. Being clear about your needs makes a difference in the decision process.

Assessing Your Business Needs and Production Requirements

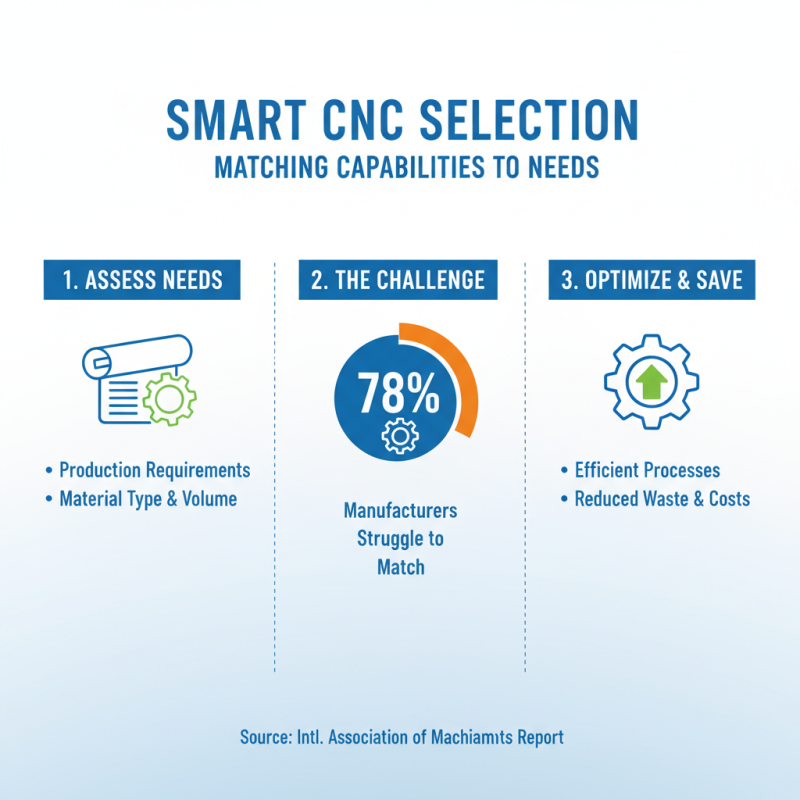

Assessing your business needs is crucial when selecting CNC machine tools. Understanding the specific production requirements ensures you make an informed decision. According to a report from the International Association of Machinists, 78% of manufacturers face challenges in matching machine capabilities with their needs. This gap often leads to inefficient processes and wasted resources.

When evaluating your production requirements, consider factors like output volume, material types, and complexity. For instance, a shop producing intricate parts in low volumes may benefit from flexible machines, while high-volume producers often need robust, dedicated equipment. A study by the National Institute of Standards and Technology shows that businesses can lose up to 30% of productivity due to mismatched machining capabilities.

Don't overlook the support and training needed for your team. Many operators struggle to adapt to new technology, resulting in errors. In fact, 60% of operators report underperforming due to insufficient training. Reflecting on these aspects can help refine your approach to choosing CNC equipment. Understanding these details shapes your investment into a machine that aligns with your goals.

Evaluating Key Features and Specifications of CNC Machines

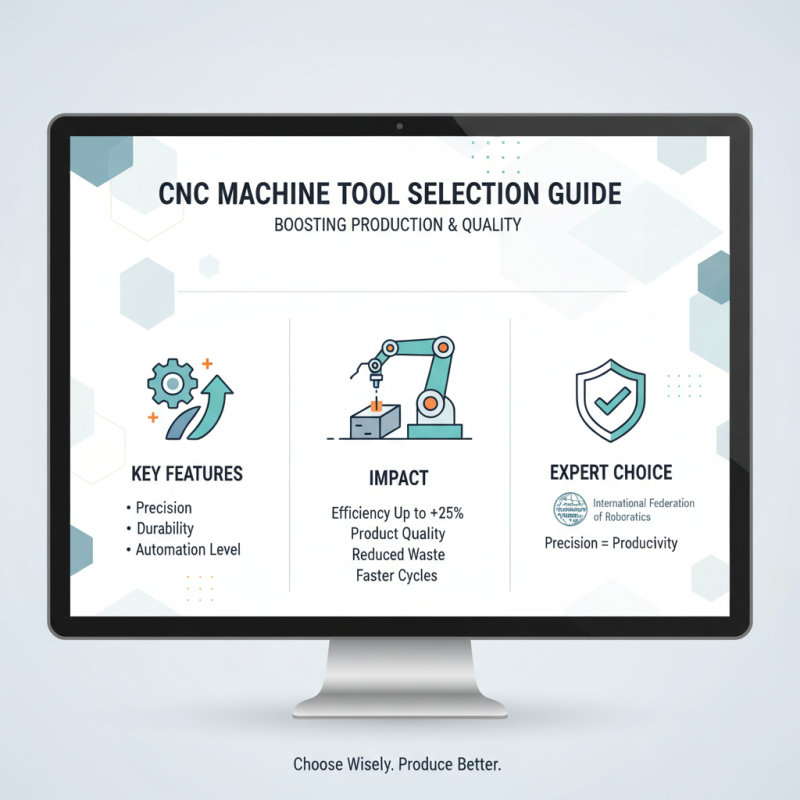

When selecting CNC machine tools, understanding key features is essential. The specifications of a CNC machine directly impact production efficiency and quality. A report from the International Federation of Robotics indicates that precision machines can boost productivity by up to 25%. This clearly shows the importance of choosing the right tool.

Consider the number of axes. Machines with more axes can handle complex parts. For example, a 5-axis CNC can create intricate shapes, reducing the need for multiple setups. Look for machines with reliable spindle speed ranges as well. A higher RPM can lead to better surface finishes and shorter cycle times.

Tips: Always assess the control software. User-friendly interfaces can significantly reduce training time. Additionally, consider the machine’s material compatibility. Not all CNC machines can handle every material type. Review the specifications carefully. Manufacturers may overstate capabilities, leading to potential issues down the line. Reflect on your specific business needs regularly to ensure your equipment stays relevant.

Considering Budget and Cost-Effectiveness in CNC Tool Selection

When selecting CNC machine tools, budget plays a crucial role. A tight budget can limit your options. It's important to find a balance between cost and quality. Cheaper machines may seem appealing, but they often lack durability. Such tools can lead to increased maintenance costs over time.

Evaluating cost-effectiveness involves more than just the initial price. Consider factors like energy consumption and tool lifespan. A machine that uses less power can save money long-term. Also, think about the training needed for your staff. Some tools require extensive training, adding to overall costs.

Reflect on your specific needs. A powerful machine might be tempting, yet it’s not always necessary. Choose based on the types of projects you handle. If precision is key, investing in accurate tools is worthwhile. Sometimes, less is more. Focus on what truly benefits your operation.

Cost Comparison of Different CNC Machine Tools

This bar chart illustrates the average cost of various CNC machine tools, which can help businesses assess their budget and cost-effectiveness in selecting the right CNC tool for their needs. Understanding these costs is essential for making informed purchasing decisions.

Researching Reliable Manufacturers and Suppliers for CNC Equipment

When selecting CNC machine tools, reliable manufacturers and suppliers are crucial. Start by assessing local options. Visit nearby shops and showrooms. Engage in conversations to gauge their expertise. A knowledgeable supplier can guide you to the right tools for your needs. It's important to ask about the machines' specifications and capabilities.

Research online for customer reviews. Platforms like forums or social media can provide insights. Look for feedback on customer service. Are previous clients satisfied? What issues did they encounter? Pay attention to red flags. If multiple reviews mention the same problem, consider alternatives.

Don't rush the decision. Take time to compare different suppliers. Develop a list of questions to ask them. Inquire about warranties and support services. How responsive are they? Prompt responses indicate strong customer care. Remember, it's not just about the price. Quality and support matter too.

Related Posts

-

Exploring the Future of Manufacturing: How CNC Machine Tools Revolutionize Precision Engineering

-

How to Achieve Precision with Fast CNC Machining Techniques?

-

Top Benefits of Fast CNC Machining for Your Manufacturing Needs

-

Top 2025 CNC Mill Models: What to Consider for Precision Machining

-

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

-

2025 Top 10 CNC Machines: Unveiling the Future of Precision Engineering and Automation