Why Choose a CNC Mill for Your Machining Needs?

Choosing the right equipment is crucial for manufacturing efficiency. A CNC mill stands out in this regard. According to John Smith, a leading expert in CNC technology, "A CNC mill offers precision and flexibility unmatched by other machines." This statement reflects the sentiments of many in the industry.

CNC mills are favored for their ability to create complex parts with ease. They operate using computer-controlled settings, ensuring consistency in production. The precision of a CNC mill can minimize waste and enhance productivity. However, it is important to acknowledge that programming a CNC mill can be challenging. New users may face a steep learning curve.

Moreover, while many benefits exist, not every application is suited to CNC milling. In some cases, traditional methods may still hold advantages. Industry leaders often rely on a mix of tools and techniques. Embracing a CNC mill means committing to continual learning and adaptation.

Advantages of CNC Mills Over Traditional Machining Methods

CNC mills offer significant advantages over traditional machining methods. One major benefit is precision. According to a study by the National Institute of Standards and Technology, CNC machines can achieve tolerances as close as ±0.005 inches. This is crucial for industries requiring meticulous specifications, such as aerospace and automotive.

Speed is another key factor. A CNC mill can operate continuously, significantly reducing production time. Reports suggest that CNC machining can cut parts 50% faster compared to manual methods. This operational efficiency leads to lower labor costs and quicker turnaround times for projects. However, some companies still struggle to fully embrace CNC technology.

Initial setup costs can be high, deterring small manufacturers. They may also face a learning curve in programming and operation. Adopting CNC technology isn't always smooth. Many workers need retraining, which adds to costs. But the long-term savings and productivity gains usually outweigh these initial challenges. Investing in CNC mills can ultimately provide companies with a significant competitive edge in today's fast-paced market.

Why Choose a CNC Mill for Your Machining Needs? - Advantages of CNC Mills Over Traditional Machining Methods

| Feature | CNC Mill | Traditional Machining |

|---|---|---|

| Precision | High precision with tolerances as low as ±0.001 inches | Moderate precision; typically ±0.005 inches |

| Automation | Fully automated, reducing human error | Manual operation often leads to variability |

| Production Speed | Faster cycle times for large production runs | Slower process due to manual setup and operation |

| Complexity of Designs | Able to produce complex geometries easily | Limited to simpler designs; more difficult to achieve complexity |

| Cost Efficiency | Lower cost per part in large volumes | Higher costs per part in production |

| Tool Change Time | Automatic tool changers reduce downtime | Manual tool changes increase production time |

Key Features and Capabilities of CNC Milling Machines

CNC milling machines offer precision and versatility for various machining needs. These machines can produce complex parts with high accuracy. One key feature is the computer numerical control system. It allows for automated, repetitive tasks. This significantly reduces human error and enhances productivity.

A common capability of CNC mills is the ability to work with multiple materials. They can handle metals, plastics, and composites. This flexibility makes them ideal for different industries. However, programming these machines can be challenging. A small mistake in the code may lead to significant errors in production.

Tips: Always double-check your code before running a job. Consider using simulation software to visualize the milling process. This helps you identify potential issues early on.

Another interesting feature is the variety of tool options available. CNC mills can switch between cutting tools effortlessly. This allows for complex designs in a single setup. Still, operators need to monitor tool wear closely. Neglecting this can result in poor surface finishes or damaged parts.

Applications of CNC Milling in Various Industries

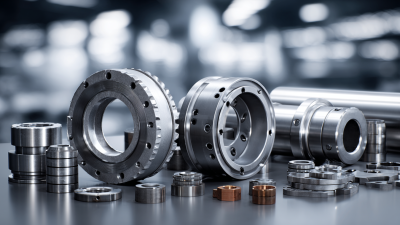

CNC milling is a versatile process used across various industries. In automotive manufacturing, it enables precise machining of complex components. A recent report from MarketsandMarkets states that the automotive CNC machine market will reach $17 billion by 2026, reflecting the growing reliance on CNC technology for high-quality parts.

In the aerospace sector, CNC milling plays a critical role. It produces intricate parts that meet stringent safety regulations. The global aerospace CNC market is projected to grow at a compound annual growth rate (CAGR) of 6.3% from 2021 to 2026. This growth showcases the industry's commitment to innovation and precision.

However, challenges persist. Many manufacturers struggle with the cost of CNC machines and maintenance. Small and medium enterprises often hesitate to invest in this technology. It's crucial for these businesses to weigh the potential benefits against their budget constraints. Despite the advantages, operators must continuously train staff to keep up with evolving CNC technologies. This ongoing investment in knowledge can seem daunting, but it’s necessary for long-term success in a competitive market.

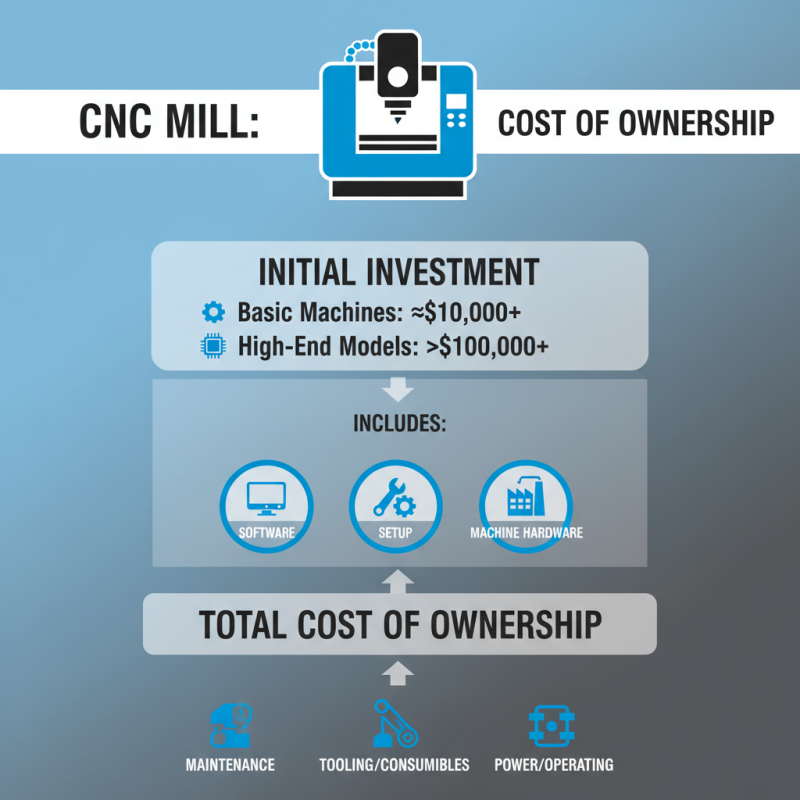

Cost Considerations When Choosing a CNC Mill

When considering a CNC mill, cost is a major factor. The initial investment can be substantial. A basic CNC milling machine may start around $10,000. Higher-end models can exceed $100,000. This cost includes the machine, software, and initial setup. However, it’s vital to assess total cost of ownership.

Operational costs must also be factored in. Energy consumption, maintenance, and tooling are ongoing expenses. Reports indicate that CNC milling machines can use up to 10 kW of power during operation. This can significantly impact utility bills. Additionally, routine maintenance can cost between $1,000 to $5,000 annually. For small businesses, these combined costs can add up quickly.

Beyond the numbers, consider the return on investment (ROI). CNC mills can improve precision and reduce waste. A study found that companies using CNC technology increased productivity by 30%. Yet, not every business sees immediate gains. Some may need time to adapt. Evaluating both costs and potential benefits is essential. Investing in a CNC mill can lead to growth, but it isn't always straightforward.

Maintenance and Support for CNC Milling Equipment

When considering CNC milling equipment, maintenance and support are essential. Regular upkeep ensures optimal performance. It prevents costly breakdowns and delays. Routine checks on lubricants and electronics can extend machine life. Operators should be trained to identify problems early. This proactive approach saves time and resources.

Support is crucial, especially during unexpected issues. Having access to a skilled technician can minimize downtime. Quick fixes can make a significant difference in productivity. However, not all support options are created equal. Researching available services matters. Some may lack responsiveness or expertise when you need it most.

Maintaining CNC machinery can sometimes feel overwhelming. Parts wear out, and technology evolves. Staying updated on maintenance practices can be a challenge for some businesses. It’s worthwhile to invest time in learning about new techniques. Building a solid relationship with support providers can alleviate some of these pressures. A reliable connection can lead to better solutions and insights for your milling needs.

Maintenance Support for CNC Milling Equipment

Related Posts

-

What is a CNC Mill and How Does It Work?

-

Exploring the Future of Precision Engineering with CNC Turning Machines

-

Unlocking Innovation: The Vital Role of Machined Parts in Modern Manufacturing Advances

-

Top 10 Benefits of Using Prototype Machined Parts for Your Projects

-

2025 Guide: How to Choose the Best Milling Machine Tools for Your Workshop

-

Top 10 CNC Milling Machines for Precision Machining in 2023