Why Choose a CNC Machine for Your Manufacturing Needs?

In the evolving landscape of manufacturing, CNC machines play a pivotal role. Expert John Smith, a seasoned engineer, notes, “CNC machines transform ideas into precision products.” This statement reflects the critical nature of these machines in today’s production processes.

CNC machines offer unmatched accuracy and efficiency. They reduce human error and ensure consistency across production runs. Many businesses benefit from the speed and reliability of CNC technology. Yet, transitioning to this advanced machinery can require significant investment and training.

While the advantages are clear, the implementation may come with challenges. Understanding software and machine intricacies can be daunting for some teams. Nevertheless, the potential for innovation and growth with CNC machines often outweighs these initial hurdles.

Benefits of CNC Machines in Enhancing Manufacturing Efficiency

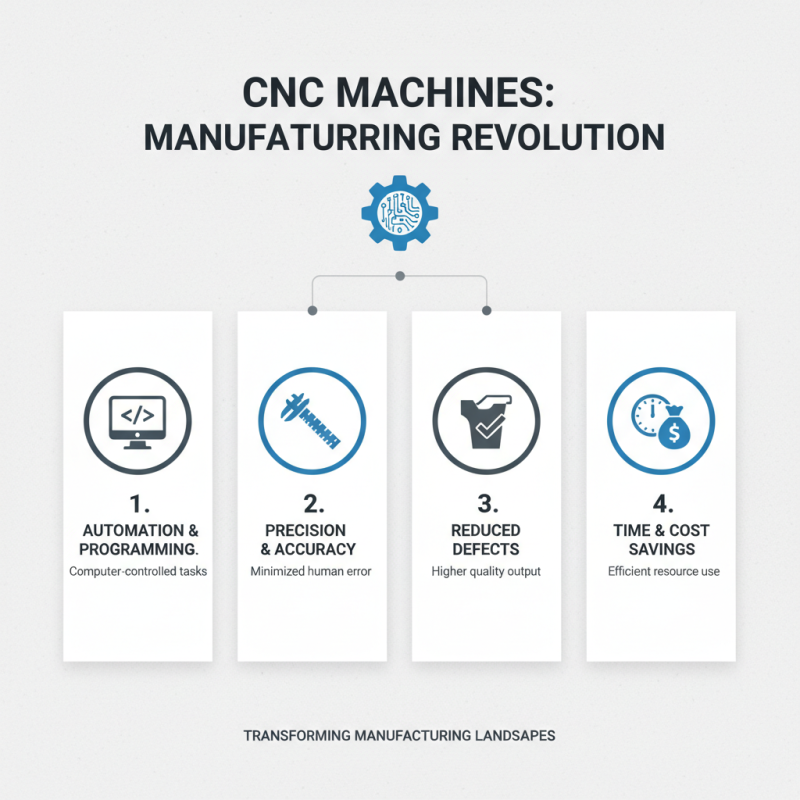

CNC machines have transformed the landscape of manufacturing. These machines utilize computer programming to automate tasks, ensuring accuracy and speed. The precision of CNC systems significantly reduces human error. Manufacturers find that this leads to fewer defects and reworks, ultimately saving time and resources.

Another advantage is the ability to produce complex shapes easily. Intricate designs are achievable with minimal manual intervention. This flexibility allows manufacturers to adapt quickly to changing market demands. However, adopting CNC technology might require initial investment and training. Some might struggle initially, but the long-term benefits are undeniable. It's essential to recognize that while CNC machines offer efficiency, they also require regular maintenance and oversight to function optimally. Investing time in training staff is crucial for leveraging these machines fully.

Cost Analysis: Comparing CNC Machines to Traditional Manufacturing Methods

CNC machines have become popular in various industries. They offer precise and consistent results. However, it’s vital to examine their costs versus traditional methods.

Traditional manufacturing often relies on manual techniques. Labor costs can be high, leading to increased overhead. Mistakes in manual processes can create waste. In contrast, CNC machines can minimize errors. They auto-correct and produce parts quickly. The initial investment in CNC technology may seem steep. However, over time, savings can accumulate due to reduced labor and waste.

Yet, CNC isn't flawless. Training staff to operate machines effectively can be costly. Maintenance is another ongoing expense. Plus, there’s a learning curve when integrating CNC into existing processes. Businesses need to weigh these factors against their production needs and goals. Is the enhanced precision worth the investment? It’s a question worth exploring.

Precision and Accuracy: Industry Standards of CNC Machining Tolerances

CNC machining is known for its precision and accuracy. In the manufacturing world, tolerances define the acceptable limits of variation in a part's dimensions. These tolerances are crucial for ensuring parts fit together seamlessly. Many industries, like aerospace and automotive, require tight tolerances to maintain safety and functionality.

Tips: Always check the specified tolerances in your projects. Even a small deviation can lead to bigger issues.

Achieving high precision in CNC machining involves several factors. The quality of the machine, the tooling, and the setup play significant roles. Even minor errors in setup can impact the final output. Operators must pay attention to every detail.

Tips: Regularly calibrate your CNC machine. This practice helps maintain consistent accuracy, but be prepared for occasional discrepancies.

Being aware of the limitations of your machinery is essential. Not every CNC machine can achieve ultra-tight tolerances, and overestimating capabilities can lead to costly mistakes. Testing and refining processes can mitigate some of these challenges.

Automation Capabilities: How CNC Machines Reduce Labor Costs

CNC machines offer remarkable automation capabilities, transforming manufacturing processes significantly. By minimizing human intervention, these machines reduce labor costs considerably. Operators can focus on monitoring instead of constant manual adjustments. This shift allows for better allocation of human resources.

The precision of CNC machines ensures consistency in production. Traditional methods often lead to variations due to human error. However, CNC machines follow programmed instructions meticulously. This control can lead to a reduction in material waste, translating into cost savings as well. Still, it's essential to consider the initial investment in CNC technology, which can be substantial for smaller manufacturers.

While automation provides efficiency, it raises questions about job displacement. Will skilled laborers lose their roles? This concern cannot be overlooked. The industry must rethink workforce training to adapt to these changes. Embracing technology is crucial, but human skills remain vital in this evolving landscape. Balancing automation with human expertise could lead to a more sustainable manufacturing future.

Why Choose a CNC Machine for Your Manufacturing Needs? - Automation Capabilities: How CNC Machines Reduce Labor Costs

| Feature | Description | Cost Savings (%) |

|---|---|---|

| Precision | CNC machines provide high accuracy and repeatability, reducing waste. | 15% |

| Speed | Faster production times lead to more output in less time. | 20% |

| Labor Reduction | Automation reduces the need for manual labor in production processes. | 30% |

| Flexibility | CNC machines can quickly switch between different tasks without extended downtime. | 10% |

| Material Efficiency | Optimized machining paths minimize material usage. | 12% |

Material Versatility: CNC Machine Applications Across Various Industries

CNC machines have become indispensable in many industries. They offer exceptional material versatility, enabling manufacturers to cut and shape various materials, from metals to plastics. This adaptability allows companies to optimize their production processes. Whether creating intricate parts for aerospace or simple components for consumer products, CNC technology excels.

In the automotive industry, CNC machines produce precise engine components. They handle tough metals like aluminum and steel efficiently. In contrast, woodworkers appreciate CNC for crafting detailed designs with less waste. However, challenges arise. Some materials, like composites, require careful handling to avoid damage. Operators must adjust settings to achieve the best results. Mistakes can lead to costly failures that hinder production.

Moreover, industries are discovering new uses for CNC technology. Medical device manufacturing benefits from this flexibility, ensuring high-quality standards. However, the learning curve can be steep. Not every material reacts the same way. Continuous testing and feedback are essential for success. As manufacturers explore more applications, they must remain adaptable. Embracing change is key to maximizing a CNC machine's potential.

Material Versatility in CNC Machining Applications

Related Posts

-

How to Choose the Right CNC Machine for Your Business Needs

-

2025 Top 10 CNC Machines: Unveiling the Future of Precision Engineering and Automation

-

Exploring the Future of Manufacturing: How CNC Machine Tools Revolutionize Precision Engineering

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

-

Maximizing Efficiency and Precision in Manufacturing with CNC Lathe Technology Insights and Trends