Top 10 Benefits of Using Prototype Machined Parts for Your Project Success

As industries strive for efficiency and innovation, the demand for prototype machined parts has surged, becoming a vital component in the design and manufacturing landscape. According to a recent industry report by Global Market Insights, the global market for prototype machining is projected to reach $15 billion by 2025, reflecting a compound annual growth rate of 7% over the next few years. This growth underscores the essential role that prototype machined parts play in expediting product development and enhancing project success.

As industries strive for efficiency and innovation, the demand for prototype machined parts has surged, becoming a vital component in the design and manufacturing landscape. According to a recent industry report by Global Market Insights, the global market for prototype machining is projected to reach $15 billion by 2025, reflecting a compound annual growth rate of 7% over the next few years. This growth underscores the essential role that prototype machined parts play in expediting product development and enhancing project success.

Expert insights further reinforce the importance of prototype machined parts. Dr. Emily Carter, a noted authority in manufacturing technologies, emphasizes that "the ability to quickly produce high-quality prototype machined parts allows businesses to iterate designs swiftly, significantly reducing time to market." This agility not only streamlines the testing phase but also mitigates risks associated with product failures, thus fostering an environment of innovation.

In a competitive landscape where time and precision are paramount, utilizing prototype machined parts can yield significant advantages. From improving design accuracy to allowing for rapid adjustments based on real-world performance, these components emerge as a cornerstone for successful project execution, paving the way for companies to stay ahead in an ever-evolving market.

Advantages of Rapid Prototyping in Product Development Efficiency

Rapid prototyping is revolutionizing product development efficiency across various industries, particularly in life sciences and healthcare. By enabling teams to swiftly create functional prototypes, this approach allows for iterative testing and refinement, which is critical in a sector where precision and innovation are paramount. The ability to rapidly prototype not only reduces time-to-market but also facilitates better collaboration among teams, as stakeholders can visualize and interact with designs long before final production. This agile methodology is essential for adapting to the fast-paced demands of modern product cycles.

Moreover, integrating advanced technologies like AI into rapid prototyping processes is transforming how companies conceptualize and design products. AI-driven tools enhance the performance of rapid prototyping by offering insights that inform design decisions and streamline engineering workflows. This synergy allows for the creation of more sophisticated medical devices and a more responsive approach to addressing user needs. As the industry shifts towards sustainable practices and advanced material usage, the potential of rapid prototyping in enhancing product development efficiency becomes even more pronounced, promising significant benefits for companies looking to innovate.

Top 10 Benefits of Using Prototype Machined Parts

This chart illustrates the top 10 benefits of using prototype machined parts in product development, highlighting the advantages of rapid prototyping in enhancing efficiency.

Cost Savings through Reduced Material Waste in Prototyping

Prototype machining is increasingly recognized for its ability to optimize project success by significantly reducing material waste, which translates into substantial cost savings. According to a report by Grand View Research, the global prototyping market is expected to reach USD 32.73 billion by 2025, driven in part by companies seeking sustainable practices. Reducing material waste not only lowers costs but also aligns with the growing emphasis on environmental sustainability in manufacturing processes.

When utilizing prototype machined parts, manufacturers can employ precise machining techniques that ensure every material cut is deliberate and necessary. A study from the American Society for Quality indicates that companies can save up to 30% on material costs by implementing advanced machining technologies during the prototyping phase. These methods allow for rapid iterations and modifications without the excessive wastage associated with traditional prototyping methods, providing both financial and environmental benefits.

Additionally, employing CNC machining can lead to a more efficient design process by allowing engineers to quickly prototype and test components. According to a report by Deloitte, businesses that integrate CNC prototyping into their workflow can see up to a 25% reduction in lead times. This efficiency further diminishes material waste, as adjustments can be made in real-time, ensuring resources are utilized effectively throughout the development cycle.

Improved Design Iteration Speed with CNC Machining Techniques

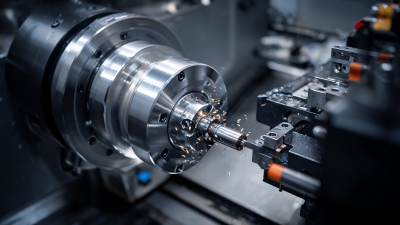

The rapid advancement of CNC machining techniques has revolutionized the way prototypes are developed, significantly enhancing design iteration speed. By employing computer-controlled machinery, engineers can produce highly accurate parts with intricate designs in a fraction of the time it took using traditional methods. This acceleration allows teams to quickly test and refine their concepts, leading to a more efficient design process.

Furthermore, the repeatability and precision of CNC machining reduce the chances of errors during the prototyping phase. Designers can implement changes based on immediate feedback, knowing that the next iteration will maintain the same high quality as the last. This iterative process not only fosters innovation but also helps in identifying potential flaws early, ultimately resulting in a more refined final product. As organizations strive for shorter development cycles, the combination of speed and accuracy offered by CNC machining proves invaluable for project success.

Enhanced Product Quality Assessment Using Precision Machined Parts

The importance of precision in manufacturing cannot be overstated, particularly when it comes to the quality assessment of machined parts. Enhanced product quality assessment using precision machined parts offers a profound advantage for industries aiming for operational excellence. With advancements in CNC machining technology, companies are now able to produce components that not only meet stringent quality standards but also improve overall project outcomes. Innovative manufacturing techniques ensure that the machined surfaces exhibit superior finish and accuracy, enhancing the durability and functionality of the final product.

Moreover, the integration of AI-enhanced quality assurance systems is transforming the landscape of manufacturing. These systems facilitate real-time defect detection, allowing for immediate corrections that minimize wasted resources and ensure product consistency. As industries lean towards sustainable practices, the use of precision machined parts contributes to reduced carbon footprints and increased efficiency. This synergy of technology and quality assurance positions businesses to thrive in a competitive market while maintaining high standards of product integrity.

Facilitation of Innovations through Early Testing and Feedback Integration

The facilitation of innovations through early testing and feedback integration is a crucial aspect of project success in today’s fast-paced industry. According to a report by Deloitte, companies that incorporate rapid prototyping into their development processes see a 50% reduction in time to market, allowing for quicker iterations based on user feedback. By utilizing prototype machined parts, engineers and designers can create functional models that closely mimic the final product, which provides invaluable insights into design flaws and usability challenges early in the process.

Moreover, early testing with prototype machined parts enables teams to gather realistic feedback from stakeholders, leading to more informed decisions and enhancements. A study by McKinsey highlights that firms using prototyping techniques gain a competitive edge, as they are able to pivot and adapt their designs effectively based on real-world interactions and testing data. This iterative approach not only minimizes costs associated with later-stage changes but also fosters a culture of innovation, where teams are empowered to explore creative solutions without the fear of failure. The integration of feedback from these early-stage prototypes ultimately drives better product outcomes and customer satisfaction.

Related Posts

-

2025 How to Choose the Best CNC Turning Center for Your Manufacturing Needs

-

The Future of Brass CNC Machining Innovations and Trends in Precision Engineering

-

2025 Top 5 Essential Lathe Machine Parts You Need for Optimal Performance

-

Exploring the Future of Manufacturing: How CNC Machine Tools Revolutionize Precision Engineering

-

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

-

Maximizing Efficiency and Precision in Manufacturing with CNC Lathe Technology Insights and Trends