2026 Best Prototype Machined Parts Trends and Innovations?

The landscape of prototype machined parts is rapidly evolving. Innovations in technology drive this growth. Companies seek faster, more efficient ways to produce parts, significantly impacting design and manufacturing.

In 2026, trends will highlight advanced materials and automation. New machining techniques promise better precision and durability. Moreover, sustainability will play a crucial role. Manufacturers are pushed to consider eco-friendly practices in their processes.

However, challenges remain. Balancing speed and quality is essential yet difficult. Many firms will need to reflect on their production methods. Navigating these trends requires a keen eye for detail and adaptability in design. The journey ahead for prototype machined parts is both promising and complex.

Emerging Materials in Prototype Machined Parts for 2026

In 2026, the prototype machined parts industry is witnessing significant innovations in materials. Emerging materials like advanced polymers and composites are leading the charge. These materials offer improved strength-to-weight ratios, enhancing the overall performance of machined parts. Reports indicate that the polymer composites market is expected to grow by over 6% annually. This trend is reshaping manufacturing processes.

Metal alloys are also evolving. Newer, lighter alloys are being developed, making prototypes more efficient. Research shows that titanium and aluminum alloys could see a rise in use by up to 15% by 2026. These materials provide excellent durability and heat resistance. However, challenges remain. The cost of sourcing these materials can be high, leading to tight budgets for some projects.

The shift to sustainable materials is another key trend. Biodegradable composites and recycled metals are gaining traction. The shift reflects a growing awareness of environmental impact. Yet, production scalability poses a problem. Many companies face difficulties in maintaining quality while transitioning to these greener options. The future of prototyping hinges on balancing innovation with practicality and cost-effectiveness.

2026 Best Prototype Machined Parts Trends and Innovations

| Material Type | Application Sector | Key Properties | Innovation Aspect |

|---|---|---|---|

| Carbon Fiber Reinforced Polymers | Aerospace | High strength-to-weight ratio, corrosion resistance | Enhanced lightweight manufacturing processes |

| Titanium Alloys | Medical Devices | Biocompatibility, lightweight | 3D printing advancements |

| Aluminum-Lithium Alloys | Automotive | Improved fuel efficiency, reduced weight | Innovative forming techniques |

| High-Performance Polymers | Electronics | Thermal stability, electrical insulation | Integration of smart technology |

| Composite Materials | Sports Equipment | Durability, flexibility | Customization and design innovation |

Advancements in CNC Machining Technology and Their Impact

The advancements in CNC machining technology are shaping the future of prototype machined parts. This evolution fosters greater precision and efficiency. Enhanced software allows for faster computations, leading to rapid prototyping. Machine tools are becoming smarter, integrating AI for better decision-making in manufacturing. This results in decreased material waste and shorter lead times.

However, not every innovation hits the mark. Some technologies may outpace training for operators, leading to potential errors in production. The steep learning curves can cause production delays. Additionally, the cost of upgrading equipment can be a burden for small manufacturers. It's crucial to find a balance between adopting new technologies and ensuring operational readiness.

Despite the challenges, the positive impacts are significant. Enhanced speed and accuracy are driving industries forward. As CNC machining continues to evolve, the potential for improved quality in prototype parts becomes clearer. Manufacturers must remain adaptable, embracing innovations while addressing their shortcomings. This will pave the way for a more efficient future in machining.

Sustainable Practices in Prototype Manufacturing for 2026

The trend towards sustainable practices in prototype manufacturing is gaining momentum as we approach 2026. Many companies are exploring eco-friendly materials like bioplastics and recycled metals. These materials not only reduce waste but also lower carbon footprints. However, the challenge lies in ensuring that these alternative materials meet the quality standards required for prototype parts.

Moreover, energy efficiency is becoming a crucial focus in the manufacturing process. Many facilities are adopting renewable energy sources, such as solar and wind. This shift not only helps the environment but can also reduce costs over time. Yet, the initial investment in renewable technologies can be daunting for small businesses, leading to hesitation.

Water usage is another pressing issue. Sustainable practices encourage the recycling of water during the production process. While many companies are making strides, some still struggle with effective implementation. There is a learning curve associated with adopting sustainable methods, and reflection on these practices is necessary for continuous improvement. As prototypes evolve, so must our approach to their manufacturing.

Integration of AI and Automation in Machining Processes

The integration of AI and automation in machining processes is reshaping the manufacturing landscape. These technologies streamline operations, reducing human error and improving efficiency. AI can analyze vast datasets to optimize machining parameters. You can expect faster prototyping and lower costs in the near future.

Tips: Look for AI tools that focus on predictive maintenance. This prevents downtime and keeps machines operating smoothly. Automation, when used wisely, can enhance productivity without sacrificing quality.

However, it’s important to consider the challenges. High upfront costs can deter some manufacturers. Not every machine is suited for automation. Understanding your current setup is crucial. Many companies still struggle with personnel training and adaptation.

Tips: Start small with automation projects. Gradually scale your efforts based on initial successes. Evaluate the ROI from AI integration closely. Every decision should align with long-term goals for maximum impact.

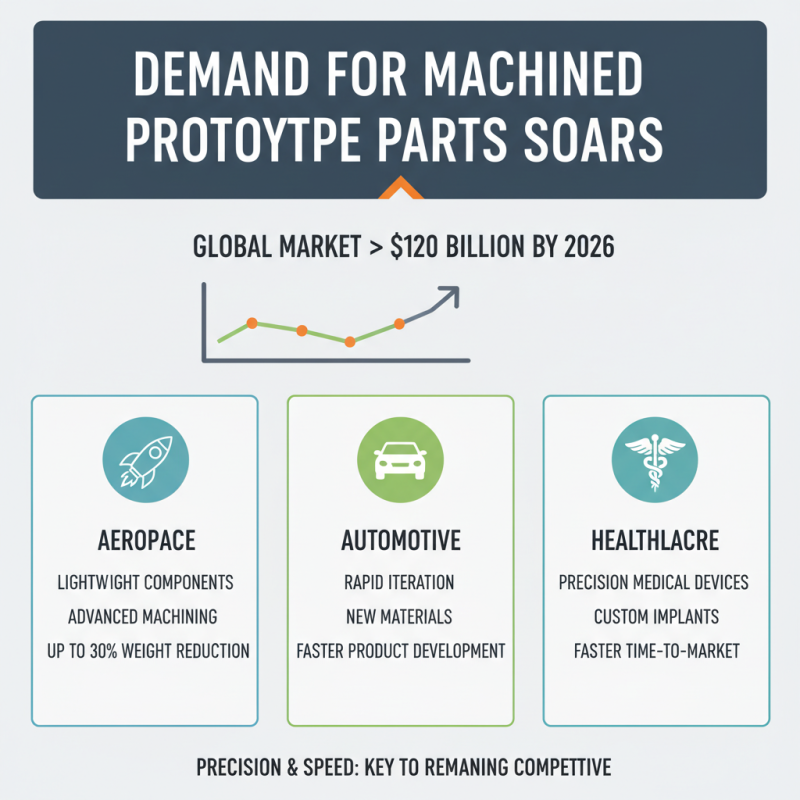

Key Industry Applications Driving Trends in Machined Prototype Parts

The demand for machined prototype parts is soaring across various industries. A recent report indicates that the global prototype machining market is expected to exceed $120 billion by 2026. This growth is largely driven by advances in aerospace, automotive, and healthcare sectors. Each sector requires precision and speed in prototyping to stay competitive. For example, in aerospace, lightweight components are critical. Using advanced machining techniques can reduce weight by up to 30%.

In addition, the automotive industry is shifting toward electric vehicles (EVs). Prototyping for EV components often requires new materials and processes. Research shows that 70% of automotive companies prioritize rapid prototyping for testing. However, challenges remain in material selection and production timelines. Sometimes, the innovative processes don’t yield expected results. This inconsistency can frustrate manufacturers looking to improve the production cycle.

Healthcare applications also highlight the need for precision. Custom medical devices and implants must fit individual specifications. Reports suggest the market for medical prototypes will grow by 15% annually. Nonetheless, there are ethical and regulatory hurdles. Ensuring safety while innovating can complicate timelines and budgets. Balancing speed and quality is a persistent challenge in this evolving landscape.

Related Posts

-

Top 10 Benefits of Using Prototype Machined Parts for Your Project Success

-

Top 10 CNC Lathe Machines for Precision Engineering in 2023

-

Top 10 CNC Milling Machines for Precision Machining in 2023

-

Top 10 CNC Turning Center Benefits Your Business Should Know?

-

How to Choose the Best CNC Machining Prototyping Techniques for Your Project

-

Top 10 CNC Turning Parts Manufacturers for Precision Engineering Solutions